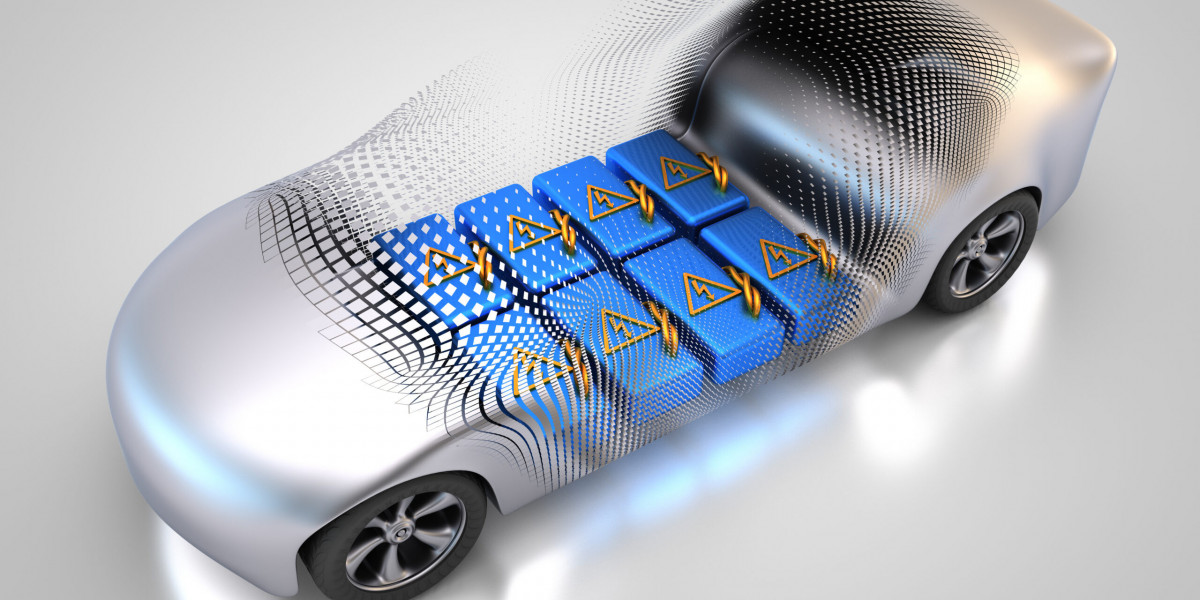

The electric vehicle battery adhesive market is rapidly growing as the demand for electric vehicles (EVs) continues to rise. Battery adhesives are essential in the assembly and maintenance of EV battery packs, offering a range of benefits such as structural integrity, thermal management, and protection from external factors. As EV technology advances and the global market for electric vehicles expands, the need for specialized adhesives to meet new performance and safety standards becomes even more critical.

Market Drivers

- Growth in EV Adoption: The rapid shift towards electric vehicles due to environmental concerns and stricter regulations is a key factor propelling the electric vehicle battery adhesive market. Governments worldwide are promoting EVs through tax incentives and subsidies, boosting consumer demand.

- Technological Innovations in Battery Chemistry: The development of advanced batteries, such as solid-state batteries, increases the need for adhesives that can meet higher thermal and chemical resistance standards. These innovations require adhesives with specialized properties to ensure battery stability.

- Focus on Lightweight Design: The trend toward lightweight materials to improve vehicle efficiency and driving range has created a demand for adhesives that are both strong and light. Adhesives offer a superior alternative to traditional fasteners, reducing the overall weight of battery packs while maintaining strength.

- Safety and Durability: EV batteries must be protected from mechanical stress, temperature variations, and external impacts. Adhesives that provide insulation, shock absorption, and resistance to high temperatures are essential in ensuring the long-term safety of EV batteries.

Challenges in the Market

- High Material Costs: Specialized adhesives required for EV battery applications are often more expensive than conventional alternatives. The high cost of these materials could impact the overall production cost of EVs, potentially affecting their market competitiveness.

- Material Compatibility: The compatibility of adhesives with different battery materials, such as lithium-ion cells, aluminum, and composites, is a challenge for manufacturers. Ensuring the adhesive's stability and performance when exposed to various conditions is essential.

- Regulatory Compliance: As governments impose stringent regulations on the automotive industry, adhesives used in EV batteries must comply with local and international standards. This adds complexity to the manufacturing process and could slow the adoption of new adhesive technologies.

Key Market Segments

- By Adhesive Type: The market for electric vehicle battery adhesives is categorized by adhesive type, including epoxy, polyurethane, silicone, and acrylate.

- Epoxy Adhesives: Known for their high strength, thermal resistance, and excellent bonding capabilities, epoxy adhesives are commonly used in EV battery packs.

- Polyurethane Adhesives: These adhesives are flexible, providing shock resistance and impact protection, which are important for battery systems exposed to vibrations.

- Silicone Adhesives: Silicone-based adhesives are valued for their high thermal stability and sealing properties, making them ideal for EV battery applications.

- Acrylate Adhesives: Acrylates are fast-curing adhesives that provide strong bonding and are used in various EV battery applications.

- By Application: The electric vehicle battery adhesive market is also segmented by application, including cell bonding, thermal management, sealing, and electrical insulation.

- Cell Bonding: Adhesives are used to securely bond individual battery cells, ensuring stability and preventing movement that could lead to damage.

- Thermal Management: Adhesives that provide thermal conductivity are crucial for dissipating heat generated by batteries during operation.

- Sealing and Encapsulation: Adhesives that seal battery packs protect them from environmental factors such as dust, moisture, and chemicals.

- Electrical Insulation: Adhesives serve as electrical insulators, preventing short circuits and enhancing the safety of EV batteries.

Regional Analysis

- Asia-Pacific: The Asia-Pacific region dominates the electric vehicle battery adhesive market due to the large number of EV manufacturers, particularly in China, Japan, and South Korea. The regions focus on electric mobility and the presence of key players in the adhesive manufacturing sector support the growth of this market.

- North America: North America is seeing increased demand for EVs, driven by policies to reduce emissions and the growing acceptance of electric vehicles among consumers. The market for electric vehicle battery adhesives is expanding due to investments in EV infrastructure and production.

- Europe: Europe has a rapidly growing electric vehicle market, bolstered by government regulations aimed at reducing CO2 emissions. This has led to increased demand for advanced adhesives in EV battery manufacturing.

Competitive Landscape

- Key Players: Leading companies in the electric vehicle battery adhesive market include Henkel AG Co. KGaA, 3M, H.B. Fuller, Sika AG, and DuPont. These companies are focused on developing innovative adhesive solutions tailored to meet the high-performance demands of EV batteries.

- Research and Development: Major players are investing in research and development to improve adhesive technologies, focusing on enhancing thermal conductivity, reducing curing times, and creating eco-friendly formulations to align with sustainability goals.

- Strategic Partnerships: Companies are forming collaborations with automakers and battery manufacturers to develop adhesive solutions that meet specific needs in EV battery systems. This collaborative approach is expected to drive the market forward.

Future Outlook

The electric vehicle battery adhesive market is expected to experience steady growth as the adoption of electric vehicles continues to rise globally. Advancements in adhesive technology will play a critical role in ensuring the safety, durability, and efficiency of EV battery systems. As manufacturers develop more efficient and cost-effective adhesives, the market will see more widespread adoption, supporting the global transition to electric mobility.