The sachet packaging machine market has witnessed steady growth due to its applications across multiple industries, including food beverages, pharmaceuticals, and personal care. However, several pain points have surfaced in the market, posing challenges to manufacturers, suppliers, and end-users. Addressing these challenges is crucial for market players looking to maintain profitability and stay ahead in the competitive landscape.

Environmental Concerns Due to Packaging Waste

- The widespread use of plastic sachets leads to significant environmental concerns, particularly in terms of waste management and pollution.

- Many sachet packaging machines rely on non-biodegradable materials, contributing to the growing environmental impact.

- As global awareness of environmental sustainability rises, governments are implementing stricter regulations on plastic waste, which increases compliance costs for manufacturers.

High Operational Costs

- Sachet packaging machines with advanced features, such as automation and customization, come with a high initial investment cost.

- Maintenance and operational expenses can also be substantial, particularly for small and medium-sized enterprises (SMEs) that may struggle with financing.

- Rising raw material costs and labor expenses add to the operational burden.

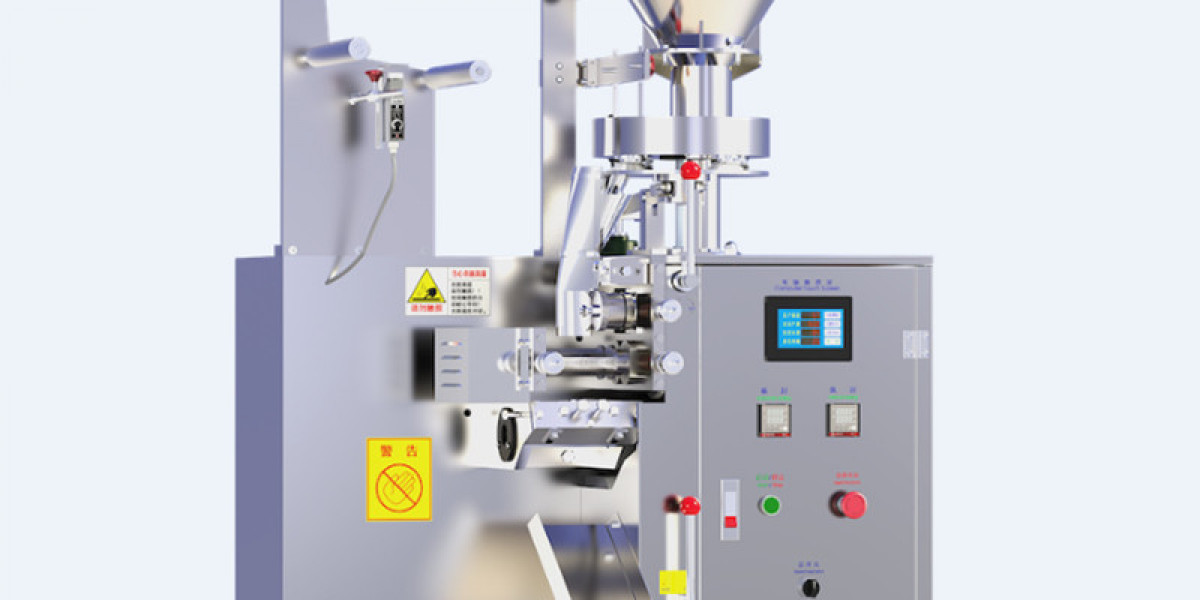

Complexity in Handling Diverse Materials

- Sachet packaging machines must handle a variety of materials, such as liquids, powders, and granular substances, which can complicate the packaging process.

- Each material type often requires a different packaging method, leading to additional costs and complexities in machine design and operation.

- Manufacturers must invest in versatile machines that can efficiently handle these materials without compromising on speed or quality.

Supply Chain Disruptions

- The global supply chain has been vulnerable to disruptions, especially due to the ongoing effects of the COVID-19 pandemic.

- Shortages of critical components or raw materials for sachet packaging machines can delay production and increase lead times.

- Supply chain challenges can result in higher costs for both manufacturers and end-users.

Challenges in Achieving Consistency in Packaging Quality

- Maintaining consistent packaging quality across large production runs is often challenging for sachet packaging machines.

- Variations in sachet weight, seal strength, or appearance can lead to product waste, reduced customer satisfaction, and increased quality control costs.

- Achieving the desired precision in terms of sachet filling and sealing can be a technical hurdle, especially for high-volume manufacturing environments.

Regulatory Challenges

- Sachet packaging is subject to stringent regulations, particularly in the pharmaceutical and food beverage industries.

- Compliance with standards for safety, hygiene, and product integrity requires significant investment in quality assurance processes.

- Regulatory updates and varying standards across regions further complicate the packaging process for international manufacturers.

Limited Customization Options in Older Machines

- Older sachet packaging machines may lack the ability to accommodate modern customization demands, such as varying sachet sizes, shapes, or designs.

- Businesses looking to offer differentiated products must invest in newer, more flexible machinery, adding to costs.

- Machines with limited customization features also restrict a companys ability to adapt to changing consumer preferences.

Inability to Meet High-Speed Production Demands

- With the increasing demand for packaged goods, manufacturers face pressure to scale up production.

- Some sachet packaging machines may not be capable of meeting the high-speed requirements of large-scale production without compromising on quality.

- Machines that are slow or prone to downtime can lead to bottlenecks, delays, and higher labor costs, impacting overall profitability.

Lack of Skilled Workforce for Operation and Maintenance

- The growing complexity of sachet packaging machines requires skilled operators who can manage and troubleshoot automated systems.

- There is often a shortage of trained personnel capable of operating advanced machinery, which affects the overall efficiency of packaging lines.

- Companies must invest in ongoing training and development to ensure the workforce is equipped to handle new technologies.

Increased Competition from Alternative Packaging Formats

- Alternative packaging formats, such as pouches, stick packs, and blisters, are gaining popularity and competing with sachets.

- These alternatives often provide similar benefits, such as convenience and cost-effectiveness, and are perceived as more sustainable in some cases.

- This competition makes it harder for sachet packaging machines to maintain their market share, especially in industries that prioritize sustainability.

Technological Obsolescence and Upgrades

- The rapid pace of technological innovation in packaging machinery means that older models of sachet packaging machines may quickly become obsolete.

- Upgrading to the latest technology is often expensive, and businesses may be reluctant to replace perfectly functional machines due to the high costs involved.

- Continuous advancements in automation, AI, and machine learning further raise the bar for sachet packaging, requiring manufacturers to stay constantly updated.