The conductive inks market has experienced significant shifts driven by advances in technology, changes in consumer demand, and the ongoing quest for eco-friendly and cost-efficient solutions. These shifts are redefining the market landscape, creating new opportunities while also presenting challenges for industry players. This article explores the key factors contributing to these market shifts and their implications for the future.

Increased Adoption of Flexible Electronics

The rise of flexible electronics is one of the most notable shifts in the conductive inks market. As consumer electronics and wearable devices become more sophisticated and lightweight, there is an increasing demand for flexible circuits and displays. Conductive inks, particularly those that can be printed on various substrates like plastic, paper, and fabric, play a vital role in this transformation. This shift has opened up new possibilities for manufacturers, pushing the market to adapt to these evolving needs.

Cost-Effectiveness and Manufacturing Efficiency

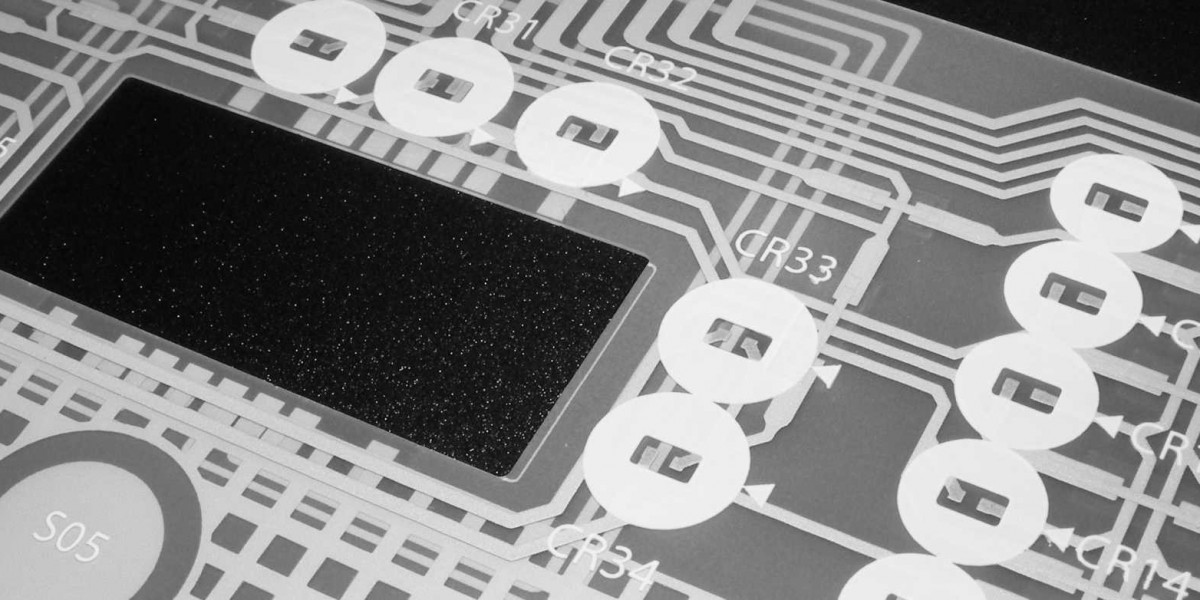

The drive for cost reduction and efficient manufacturing processes has led to the growing use of conductive inks in printed electronics. Traditional methods of producing electronic components, such as using metallic wires and complex assembly techniques, are being replaced by more streamlined printing technologies. Inkjet and screen printing, which are widely used for applying conductive inks, offer the advantages of reducing production costs and material wastage. This shift is enabling manufacturers to produce electronics at a much lower cost while maintaining high performance.

Emergence of Eco-Friendly Materials

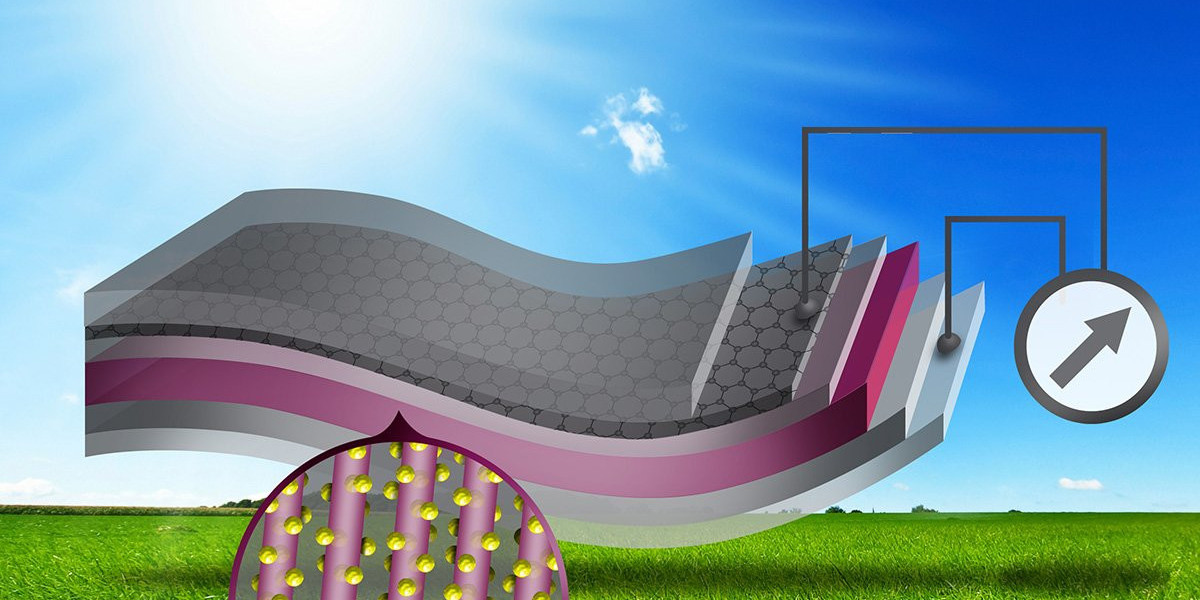

Environmental concerns have driven a shift toward the use of eco-friendly and sustainable materials in the conductive inks market. Traditional conductive inks, often based on silver, have raised environmental issues due to mining and production processes. In response, manufacturers are exploring alternative materials such as copper, graphene, and carbon-based inks that are not only less expensive but also more environmentally friendly. This shift is crucial as consumers and businesses alike become more eco-conscious, which is expected to shape the market's future trajectory.

Technological Advancements in Printing Techniques

Printing technologies have seen considerable advancements, facilitating the production of more intricate and efficient designs using conductive inks. The evolution of inkjet printing, flexographic printing, and screen printing has made it possible to print high-quality electronic circuits on flexible and unconventional substrates. These innovations allow for the creation of sophisticated printed electronics like sensors, antennas, and displays. As printing techniques continue to improve, the market will see even more opportunities for innovative applications across various industries.

Diversification of Application Areas

The range of applications for conductive inks has expanded, thanks to their versatility. Initially used in electronics, conductive inks are now finding applications in sectors like automotive, healthcare, and energy. In automotive applications, conductive inks are used in smart windows, flexible dashboards, and electronic control units. In healthcare, they are used in sensors and diagnostic tools. Additionally, the renewable energy sector has increasingly adopted conductive inks in the production of organic solar cells and other energy-efficient devices. This diversification of applications is one of the most prominent shifts, contributing to the market's growth and increased demand.

Integration with Internet of Things (IoT)

Another significant market shift has been the growing integration of conductive inks in IoT devices. The proliferation of connected devices, such as smart home products, wearable health monitors, and connected cars, has created a demand for flexible and lightweight electronic components. Conductive inks are essential for the development of these devices as they provide the necessary conductive pathways while maintaining the lightweight and flexible nature required for these applications. This trend is expected to further accelerate as IoT devices become increasingly embedded in everyday life.

Rising Demand for Smart Packaging

Smart packaging is another sector where the conductive inks market is experiencing growth. Conductive inks are used in packaging for interactive features such as RFID tags, sensors for temperature monitoring, and security devices. As consumer demand for smart packaging continues to grow, manufacturers are adopting conductive inks to create packaging solutions that enhance product safety, traceability, and consumer engagement. This shift in the packaging industry is creating new market opportunities for conductive ink manufacturers, particularly in sectors like food, healthcare, and logistics.

Challenges from Material Limitations

While the advancements in conductive inks have been substantial, there are still challenges related to material limitations. Silver-based inks, although effective, are costly, leading to research into alternative conductive materials. The ongoing development of copper, carbon, and graphene-based inks is designed to offer better performance at a lower cost. However, these alternatives have yet to match the high conductivity levels of silver-based inks. Overcoming these limitations will be a key factor in the long-term success of the conductive inks market.

Market Consolidation and Collaboration

The market is also witnessing a trend toward consolidation and collaboration among key industry players. Companies in the conductive inks market are increasingly partnering with one another to leverage complementary expertise, expand their product portfolios, and access new markets. This shift is expected to accelerate innovation and speed up the development of new conductive ink solutions. Strategic mergers and acquisitions, along with joint ventures, will continue to play a crucial role in shaping the competitive landscape.

Regional Shifts in Demand

Geographically, the demand for conductive inks is shifting toward Asia-Pacific, driven by the increasing production of consumer electronics, automotive applications, and wearable devices in countries like China, Japan, and South Korea. These regions are rapidly adopting conductive inks due to their cost-effectiveness and the growing need for advanced electronic components. As Asia-Pacific continues to dominate the global manufacturing sector, the region's influence on the conductive inks market is set to expand further.