I am mpradipmm3 (mpradipmm3@gmail.com). I hold full responsibility for this content, which includes text, images, links, and files. The website administrator and team cannot be held accountable for this content. If there is anything you need to discuss, you can reach out to me via mpradipmm3@gmail.com email.

Disclaimer: The domain owner, admin and website staff of New York City US, had no role in the preparation of this post. New York City US, does not accept liability for any loss or damages caused by the use of any links, images, texts, files, or products, nor do we endorse any content posted in this website.

Additive manufacturing, commonly known as 3D printing, has emerged as a transformative technology that revolutionizes the way we design, prototype, and manufacture a wide range of products. Unlike traditional subtractive manufacturing processes, which involve cutting, drilling, or machining material from a solid block, additive manufacturing builds objects layer by layer using digital design files and additive techniques. In this comprehensive guide, we will explore the principles of additive manufacturing, its applications across various industries, the advantages and challenges of 3D printing, and the future outlook of this innovative technology.

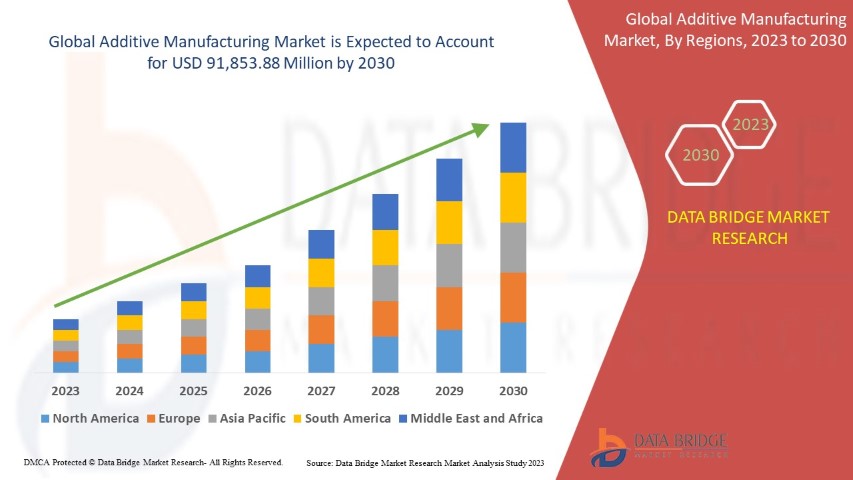

To Acquire More Visit: https://www.databridgemarketresearch.com/reports/global-additive-manufacturing-market

Principles of Additive Manufacturing:

Additive manufacturing encompasses a diverse range of techniques and technologies, but the fundamental principles remain consistent across different processes. Key principles of additive manufacturing include:

-

Digital Design: The additive manufacturing process begins with the creation of a digital 3D model using computer-aided design (CAD) software. The digital model defines the geometry, dimensions, and specifications of the object to be produced, allowing for precise customization and optimization.

-

Layer-by-Layer Fabrication: Additive manufacturing builds objects layer by layer, following the instructions from the digital design file. Each layer is deposited or cured sequentially, gradually building up the final three-dimensional structure. This layer-by-layer approach enables complex geometries and intricate designs that are difficult or impossible to achieve with traditional manufacturing methods.

-

Material Deposition or Solidification: Additive manufacturing processes utilize various materials, including plastics, metals, ceramics, and composites, depending on the specific application and requirements. Materials are deposited, fused, sintered, cured, or solidified layer by layer to form the desired object. Different additive manufacturing techniques employ different mechanisms for material deposition and consolidation, such as extrusion, powder bed fusion, vat polymerization, and binder jetting.

-

Post-Processing and Finishing: Once the object is fabricated using additive manufacturing, post-processing steps may be required to remove support structures, improve surface finish, and enhance mechanical properties. Post-processing techniques may include sanding, polishing, painting, heat treatment, or secondary machining operations to achieve the desired final product quality.

Applications of Additive Manufacturing:

Additive manufacturing has revolutionized production processes across a wide range of industries, opening up new possibilities for design innovation, rapid prototyping, customization, and on-demand manufacturing. Some notable applications of additive manufacturing include:

-

Aerospace and Defense: Additive manufacturing is widely used in the aerospace and defense industries for producing lightweight, complex components with high strength-to-weight ratios. Aircraft engine parts, structural components, tooling, and unmanned aerial vehicle (UAV) prototypes are often manufactured using additive techniques to reduce weight, improve performance, and accelerate development cycles.

-

Automotive: In the automotive industry, additive manufacturing is employed for rapid prototyping, customized tooling, and low-volume production of vehicle components. Automotive manufacturers use 3D printing to create concept models, functional prototypes, interior trim parts, brake calipers, and lightweight components for electric vehicles (EVs) and hybrid vehicles.

-

Healthcare and Biomedical: Additive manufacturing plays a crucial role in the healthcare sector for producing patient-specific medical devices, prosthetics, implants, and anatomical models. Medical professionals utilize 3D printing to create custom implants, surgical guides, dental restorations, orthotic devices, and patient-specific anatomical models for preoperative planning and surgical simulation.

-

Consumer Goods: Additive manufacturing enables customization and personalization of consumer products, including jewelry, fashion accessories, home decor items, and electronic gadgets. Consumers can design and customize products according to their preferences, leading to greater product diversity, consumer engagement, and market differentiation.

-

Architecture and Construction: In the architecture and construction industries, additive manufacturing is used for rapid prototyping of architectural models, scale models, and building components. Large-scale 3D printers can fabricate building elements, facades, partitions, and decorative features using a variety of materials, including concrete, polymers, and recycled materials.

Advantages of Additive Manufacturing:

Additive manufacturing offers several advantages over traditional manufacturing methods, including:

-

Design Flexibility: Additive manufacturing enables the creation of complex geometries, lattice structures, and customized designs that are not feasible with conventional manufacturing processes. Designers have greater freedom to optimize parts for specific functions, reduce material usage, and minimize assembly requirements.

-

Rapid Prototyping: Additive manufacturing accelerates the product development cycle by enabling rapid prototyping and iterative design iterations. Design changes can be implemented quickly and cost-effectively, allowing for faster concept validation, design validation, and product refinement.

-

On-Demand Manufacturing: Additive manufacturing facilitates on-demand production of customized, low-volume, or one-of-a-kind products without the need for expensive tooling or molds. Manufacturers can respond rapidly to market demands, produce small batches economically, and offer personalized products tailored to individual customer preferences.

-

Material Efficiency: Additive manufacturing minimizes material waste by only depositing or solidifying material where it is needed, reducing material consumption and environmental impact. Unused material can often be recycled or reused, further enhancing sustainability and resource efficiency.

-

Supply Chain Resilience: Additive manufacturing enhances supply chain resilience by decentralizing production and reducing reliance on centralized manufacturing facilities. Distributed manufacturing networks can be established to produce parts locally, reduce lead times, mitigate supply chain disruptions, and improve responsiveness to changing market conditions.

Challenges and Limitations:

Despite its numerous advantages, additive manufacturing also faces several challenges and limitations, including:

-

Material Selection and Performance: The range of materials suitable for additive manufacturing is more limited compared to traditional manufacturing processes, particularly for high-performance applications requiring specific mechanical, thermal, or chemical properties. Materials must also meet stringent quality and certification requirements for safety-critical applications.

-

Process Control and Quality Assurance: Additive manufacturing processes require precise control of process parameters, environmental conditions, and material properties to ensure consistent part quality and performance. Variability in process parameters, build conditions, or material properties can lead to defects, porosity, or dimensional inaccuracies that compromise part integrity.

-

Post-Processing Requirements: Many additive manufacturing processes require extensive post-processing steps to achieve the desired surface finish, mechanical properties, and dimensional accuracy. Post-processing operations can add time, cost, and complexity to the manufacturing process, offsetting some of the benefits of rapid prototyping and on-demand manufacturing.

-

Scalability and Production Volume: Additive manufacturing may be less cost-effective than traditional manufacturing methods for large-scale production volumes due to slower build rates, limited throughput, and higher material costs. Scaling up additive manufacturing processes to meet high-volume production demands remains a challenge, particularly for metal additive manufacturing technologies.

-

Intellectual Property and Regulatory Considerations: Additive manufacturing raises complex legal and regulatory issues related to intellectual property rights, patent infringement, quality standards, and regulatory compliance. Protecting intellectual property, ensuring data security, and complying with industry regulations are critical considerations for manufacturers adopting additive manufacturing technologies.

Future Outlook and Emerging Trends:

Despite the challenges, additive manufacturing continues to evolve rapidly, driven by advancements in materials science, process technology, and digital innovation. Emerging trends in additive manufacturing include:

-

Multi-Material and Multi-Process Integration: Advances in multi-material printing and multi-process integration enable the fabrication of complex, multi-functional parts with heterogeneous properties. Hybrid additive manufacturing systems combine different printing technologies, such as powder bed fusion, directed energy deposition, and material extrusion, to achieve greater versatility and performance.

-

Industry 4.0 Integration: Additive manufacturing is increasingly integrated with digital manufacturing platforms, automation systems, and data analytics tools as part of the Industry 4.0 paradigm. Smart factories leverage digital twin technology, real-time monitoring, and predictive maintenance to optimize production workflows, improve quality control, and enhance productivity.

-

Additive Manufacturing for Sustainable Development: Additive manufacturing contributes to sustainable development goals by reducing material waste, energy consumption, and carbon emissions compared to traditional manufacturing methods. Sustainable materials, bio-based polymers, and recycled feedstocks are being explored to further enhance the environmental sustainability of additive manufacturing processes.

-

In-Situ Process Monitoring and Quality Control: In-situ process monitoring and real-time quality control systems enable proactive detection of defects, process anomalies, and material inconsistencies during additive manufacturing. Advanced sensing technologies, machine learning algorithms, and artificial intelligence (AI) techniques enhance process reliability, part quality, and manufacturing efficiency.

-

Additive Manufacturing in Space Exploration: Additive manufacturing holds great promise for space exploration missions, where on-demand manufacturing of spare parts, tools, and structural components can reduce reliance on Earth-based supply chains and enable long-duration space missions. In-space additive manufacturing technologies are being developed to fabricate mission-critical parts using lunar regolith, Martian soil, or recycled spacecraft materials.

Conclusion:

In conclusion, additive manufacturing represents a paradigm shift in manufacturing technology, offering unprecedented opportunities for innovation, customization, and sustainability across various industries. As additive manufacturing continues to advance, its widespread adoption will depend on addressing technical challenges, enhancing material capabilities, and integrating digital technologies into manufacturing workflows. By harnessing the full potential of additive manufacturing, manufacturers can drive product innovation, streamline production processes, and create new value propositions for customers in an increasingly digital and interconnected world. Through collaboration, research, and investment in additive manufacturing technologies, we can unlock new frontiers of creativity, efficiency, and sustainability in the manufacturing industry, shaping the future of production for generations to come.