Introduction to Custom Blister Foil Packaging

Custom blister foil packaging is a specialized form of packaging used across various industries to protect and display products in a secure and visually appealing manner. Unlike traditional packaging methods, custom blister foil packaging offers flexibility in design, allowing businesses to tailor packaging solutions according to their specific needs and requirements.

Benefits of Custom Blister Foil Packaging

Protection and Security

Custom blister foil packaging provides excellent protection against external elements such as moisture, light, and tampering. Its sturdy construction ensures that products remain intact during storage, transportation, and display, reducing the risk of damage or contamination.

Visibility and Branding

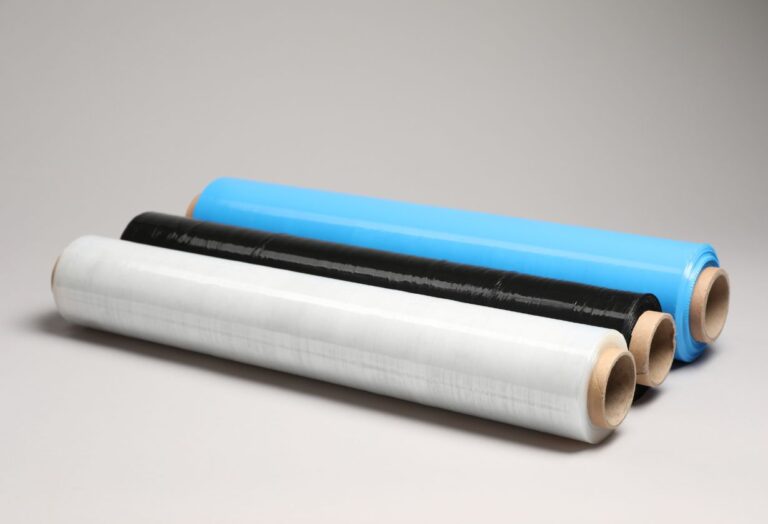

One of the key advantages of custom blister foil packaging is its ability to showcase products effectively. Clear plastic or foil materials allow consumers to see the contents of the package, enhancing product visibility and attracting attention on retail shelves. Moreover, customizable branding options enable businesses to reinforce their brand identity and communicate essential product information to consumers.

Key Features of Custom Blister Foil Packaging

Material Durability

Custom blister foil packaging is typically made from high-quality materials such as PVC, PET, or aluminum foil, ensuring durability and longevity. These materials are resistant to tearing, puncturing, and environmental factors, maintaining the integrity of the packaged products throughout their lifecycle.

Form and Function

The versatile design of custom blister foil packaging allows for the creation of various shapes, sizes, and configurations to accommodate different product types and specifications. Whether it’s a single-item blister pack or a multi-compartment tray, manufacturers can tailor packaging solutions to meet specific application requirements.

Applications of Custom Blister Foil Packaging

Pharmaceuticals

In the pharmaceutical industry, custom blister foil packaging is widely used for packaging tablets, capsules, and other dosage forms. The tamper-evident seals and barrier properties of blister packs ensure product safety and compliance with regulatory standards, making them ideal for dispensing and consumer use.

Electronics

Electronics manufacturers rely on custom blister foil packaging to protect sensitive components and devices from physical damage and electrostatic discharge. Blister packs with anti-static properties help prevent static buildup and protect electronic products during storage, shipping, and handling.

Design Considerations for Custom Blister Foil Packaging

Size and Shape

When designing custom blister foil packaging, considerations such as product dimensions, weight, and shape play a crucial role in determining the optimal packaging solution. By selecting the right size and configuration, businesses can minimize material waste and optimize storage space while ensuring a snug fit for the packaged products.

Graphics and Branding

Custom blister foil packaging offers ample opportunities for branding and product promotion through vibrant graphics, logos, and artwork. Whether it’s a full-color print or embossed logo, businesses can leverage packaging design to create a memorable brand experience and differentiate their products from competitors.

Custom Blister Foil Packaging Manufacturing Process

The manufacturing process of custom blister foil packaging involves several steps, starting from material selection to final packaging. Here’s an overview of the typical process:

Material Selection

The first step in manufacturing custom blister foil packaging is selecting the appropriate materials based on the desired properties and specifications. Factors such as barrier protection, clarity, and recyclability are taken into account to ensure the suitability of the packaging materials for the intended application.

Tooling and Molding

Once the materials are chosen, custom molds and tooling are created to shape the blister packs according to the desired dimensions and configurations. Precision molding techniques ensure consistent quality and accuracy, allowing for seamless integration with automated packaging systems.

Sealing and Packaging

After the blister packs are formed, they are sealed using heat or pressure to enclose the products securely. Depending on the application, additional features such as tamper-evident seals, perforations, or hang holes may be incorporated to enhance functionality and consumer convenience.

Environmental Impact and Sustainability

Recyclability

As environmental concerns continue to grow, manufacturers are increasingly focusing on sustainable packaging solutions, including recyclable blister foil materials. By choosing recyclable materials such as PET or PP, businesses can reduce their carbon footprint and support a circular economy while meeting consumer demands for eco-friendly packaging options.

Material Reduction

Another approach to enhancing the sustainability of custom blister foil packaging is through material reduction and lightweighting. By optimizing packaging design and minimizing excess material usage, manufacturers can decrease resource consumption and minimize waste generation without compromising product protection or quality.

Cost Considerations and ROI

Initial Investment

While custom blister foil packaging may require an initial investment in tooling and equipment, the long-term benefits often outweigh the upfront costs. By reducing product damage, improving shelf visibility, and enhancing brand perception, custom packaging solutions can lead to increased sales and profitability over time.

Long-term Savings

In addition to direct cost savings, custom blister foil packaging offers indirect benefits such as reduced product returns, lower shipping expenses, and improved inventory management. By investing in durable and reliable packaging solutions, businesses can minimize operational expenses and maximize efficiency throughout the supply chain.

Choosing the Right Custom Blister Foil Packaging Supplier

Reputation and Experience

When selecting a custom blister foil packaging supplier, businesses should prioritize companies with a proven track record of quality and reliability. Experienced suppliers with industry expertise can offer valuable insights and guidance throughout the packaging design and manufacturing process, ensuring optimal results and customer satisfaction.

Quality Control Measures

To maintain product integrity and consistency, it’s essential to partner with a supplier that implements stringent quality control measures and adheres to regulatory standards. From raw material inspection to final product testing, robust quality assurance processes help identify and address any potential issues or defects before they impact the end-user.

Future Trends and Innovations

Smart Packaging Technologies

With advancements in IoT (Internet of Things) and sensor technology, the future of custom blister foil packaging is increasingly focused on smart packaging solutions. From RFID tags to temperature sensors, smart packaging enables real-time monitoring and tracking of products, enhancing supply chain visibility and consumer engagement.

Sustainable Materials

As sustainability becomes a top priority for consumers and businesses alike, the demand for eco-friendly blister foil packaging materials is expected to rise. Innovations such as biodegradable plastics, compostable films, and plant-based polymers offer promising alternatives to traditional packaging materials, reducing environmental impact and supporting a circular economy.

Conclusion

Custom blister foil packaging offers a versatile and effective solution for protecting and showcasing products across various industries. Businesses can leverage custom packaging design from pharmaceuticals to electronics to enhance brand visibility, ensure product integrity, and meet evolving consumer preferences. By prioritizing sustainability, innovation, and quality, companies can stay ahead of the competition and drive long-term success in the dynamic packaging market.

FAQs

What industries commonly use custom blister foil packaging?

Custom blister foil packaging is commonly used in pharmaceuticals, electronics, consumer goods, and food packaging industries.

Is custom blister foil packaging recyclable?

Many custom blister foil packaging materials are recyclable, including PET, PP, and aluminium foil, making them environmentally friendly options for businesses.

How does custom blister foil packaging contribute to branding efforts?

Custom blister foil packaging offers ample opportunities for branding through vibrant graphics, logos, and artwork, helping businesses create a memorable brand experience and stand out on retail shelves.

Can custom blister foil packaging be customized for irregularly shaped products?

Custom blister foil packaging can be tailored to accommodate irregularly shaped products through custom moulds and tooling, ensuring a snug fit and maximum protection.

What are some eco-friendly alternatives to traditional blister foil packaging?

Eco-friendly alternatives to traditional blister foil packaging include biodegradable plastics, compostable films, and plant-based polymers, which offer sustainable solutions for businesses looking to reduce their environmental impact.