Conveyors are essential equipment in many industries, providing a convenient and efficient way to move goods and materials. However, like any machinery, conveyors require regular maintenance to ensure smooth operations and to extend their lifespan.

Neglecting maintenance can lead to costly repairs, production downtime, and even safety hazards. That said, it’s worth noting that maintenance procedures may vary depending on the type of conveyor.

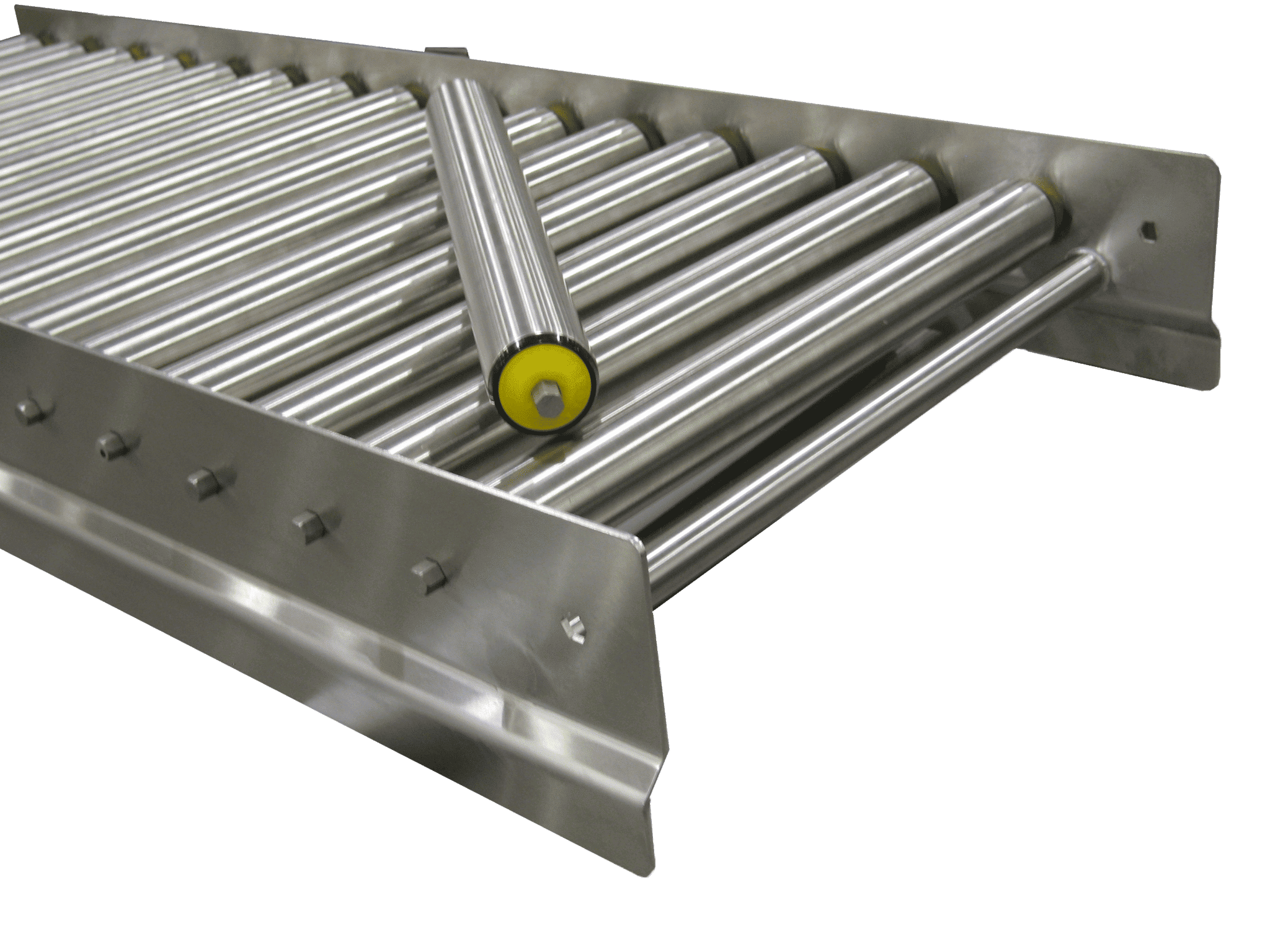

This post discusses some essential maintenance tips for conveyors that use rollers to help keep them running smoothly.

Regular Cleaning

Keeping the roller conveyor clean is crucial for its performance and longevity. Dust, debris, and product residue can accumulate on the rollers, causing friction and affecting their rotation ability.

Regularly sweep or vacuum the conveyor to remove any loose material. You should also consider using a mild detergent and water solution to clean the rollers. This ensures that the rollers are free from any sticky substances.

You should also remember to dry the rollers thoroughly before resuming operation.

Check for Wear and Tear

Routine inspection is essential to identify any signs of wear and tear in any machinery. Check the rollers, frames, and bearings for any signs of damage, such as cracks, dents, or excessive wear.

Replace any damaged or worn-out components immediately to prevent further damage and potential breakdowns. Regular inspections can help catch issues early on, saving you costly repairs and production interruptions.

Lubrication

Proper lubrication is vital for the smooth operation of rollers. Apply lubricant to the bearings, rollers, and chains as recommended by the manufacturer.

Lubrication reduces friction and wear, ensuring that the rollers rotate freely. You should, however, be cautious not to over-lubricate, as excessive lubrication can attract more dust and debris, leading to clogging and other issues.

Follow the manufacturer’s guidelines for the appropriate type and frequency of lubrication.

Belt Tension

If your roller conveyor utilizes a belt system, it is crucial to check and maintain proper belt tension. A loose or overly tight belt can cause slipping and misalignment, negatively impacting the conveyor’s performance.

Regularly check the tension of the belt, and adjust it as necessary to ensure it is within the manufacturer’s recommended specifications. A correctly tensioned belt will ensure optimal power transmission and prevent unnecessary wear and tear.

Inspect Guards and Safety Devices

Safety should always be a top priority in maintaining conveyors. To this end, machinery should have guards and safety devices to protect workers from potential accidents and injuries.

To avoid such hazards, regularly inspect and ensure that these safety features are in good condition. You also need to check for any loose or missing guards, and repair or replace them as needed.

It’s also essential that you check emergency stop buttons and other safety devices for proper functionality.

Training and Education

Properly trained and educated staff can play a crucial role in the maintenance of conveyors. With this in mind, train your employees on how to operate the conveyors safely and effectively.

Provide both technicians and operators with knowledge of common maintenance tasks and the ability to identify potential issues. Encourage them to report any abnormalities promptly, as prompt action can prevent smaller problems from escalating into larger ones.

Keep Spare Parts on Hand

Despite regular maintenance, unexpected breakdowns can still occur. To minimize downtime and disruption to your operations, it is advisable to keep a stock of commonly needed spare parts.

This includes items such as rollers, bearings, belts, and chains. Having spare parts readily available allows for quick replacement, reducing the time it takes to get your roller conveyor back up and running.

Consult the Manufacturer

Consult the manufacturer’s guidelines and recommendations for specific maintenance requirements. Each conveyor system may have unique maintenance needs, and the manufacturer’s instructions provide valuable insights into the proper care and maintenance of your equipment.

Follow their guidelines for maintenance schedules, lubricants, and any other recommended practices.

Why is Maintenance Important for Conveyor Systems

Regular maintenance is essential for ensuring the smooth operation of conveyors. Clean the conveyors regularly, check for wear and tear, and lubricate the necessary components.

You also need to maintain proper belt tension, inspect guards and safety devices, and provide training to your staff. Other considerations include keeping spare parts on hand for quick replacements and consulting the manufacturer’s guidelines for specific maintenance requirements.

By implementing these maintenance tips, you can extend the lifespan of your conveyors, prevent costly breakdowns, and ensure the safety and efficiency of your operations.