The electronics adhesives market is witnessing significant shifts, driven by advancements in technology, changing consumer needs, and environmental considerations. These shifts are reshaping the industry by introducing new applications and opportunities, presenting challenges for manufacturers, and demanding innovation in adhesive formulations. As industries evolve, understanding these changes is crucial for companies in the electronics sector to remain competitive and responsive to market demands.

Technological Advancements Driving Market Growth

- Development of conductive adhesives to enhance performance in electronics.

- Advancements in pressure-sensitive adhesives, used in flexible electronics and displays.

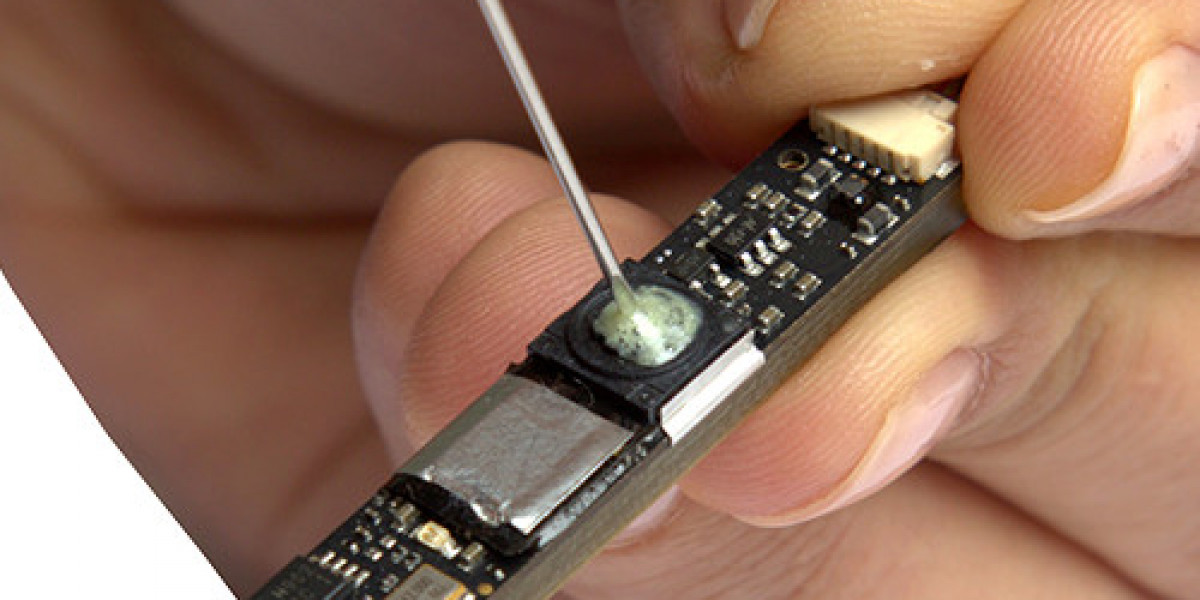

- Rise in demand for adhesives that meet the high-performance needs of miniaturized electronics.

- Increasing reliance on nanomaterials in adhesive production to improve conductivity and reliability.

- Application of adhesives in 3D printing technologies for electronics assembly.

Consumer Preferences Shaping Product Demand

- Growing demand for eco-friendly and sustainable adhesives in consumer electronics.

- Increased consumer interest in lightweight, durable electronics, leading to new adhesive formulations.

- Preference for adhesives with higher thermal and chemical resistance for use in advanced gadgets.

- Rising awareness of health and safety concerns regarding adhesive components, pushing for non-toxic materials.

- Expansion of wearable electronics creating a need for more flexible and stronger adhesives.

Environmental Considerations and Regulations

- Regulatory pressure on reducing hazardous substances in electronic components and adhesives.

- Increased focus on biodegradable adhesives to meet environmental sustainability standards.

- Changes in government policies promoting the use of low-VOC (Volatile Organic Compounds) adhesives.

- The implementation of stricter environmental regulations influencing the development of adhesives that support recycling and waste reduction.

- Efforts to minimize the carbon footprint of adhesive manufacturing processes.

Competitive Landscape and Market Fragmentation

- Emergence of new players entering the market with specialized, high-performance adhesives.

- Increasing consolidation among adhesive manufacturers to optimize production capabilities and innovation.

- Presence of a few large players dominating the market, but small- to medium-sized enterprises focusing on niche markets.

- Increased investment in RD by major companies to maintain technological leadership.

- Expansion of manufacturing capacities and global reach by key players to capture emerging markets.

Impact of Global Supply Chain Dynamics

- Disruptions in the global supply chain affecting the availability and cost of raw materials for adhesives.

- Shortage of key raw materials such as epoxy resins and curing agents affecting production timelines.

- Geopolitical tensions leading to instability in adhesive supply chains and increased raw material prices.

- Focus on localizing adhesive manufacturing to reduce dependency on international imports.

- Efforts to diversify the supply base to mitigate risks related to supply chain disruptions.

Market Expansion and Regional Trends

- Growth of the electronics adhesives market in emerging economies such as China, India, and Southeast Asia.

- Adoption of next-generation electronics in the automotive and healthcare industries fueling demand for specialized adhesives.

- Shift in demand from traditional adhesives to high-performance solutions in developed markets like North America and Europe.

- Increasing investments in the Asia-Pacific region due to the high concentration of electronics manufacturing activities.

- Regional regulatory differences influencing the development of adhesives for specific markets, creating customized solutions.

Rising Demand for Customized Adhesive Solutions

- Need for adhesives tailored to meet the specific needs of high-tech electronics such as smartphones, laptops, and wearables.

- Growing trend toward the development of adhesives with multifunctional properties like thermal conductivity and UV resistance.

- Customization of adhesive properties to ensure compatibility with different substrates in complex electronic assemblies.

- Collaboration between adhesive manufacturers and electronic device manufacturers to design bespoke adhesive solutions.

- Shift towards adhesives designed for miniaturized electronic devices, requiring greater precision and performance.

Key Challenges in Electronics Adhesives Market

- Difficulty in maintaining the balance between high adhesive strength and low environmental impact.

- Challenges in achieving uniform performance across diverse electronic applications.

- Ensuring that adhesives do not compromise the aesthetic quality or finish of electronic devices.

- Meeting stringent certification standards in various regions while keeping production costs competitive.

- Managing the complex formulations required for adhesives that must function under extreme conditions.

Increased Research and Development in Adhesive Formulations

- Growing focus on creating adhesives that are both high-performance and sustainable.

- Efforts to develop heat-resistant adhesives to support increasingly complex and high-powered electronic systems.

- Research into adhesives that can endure extreme conditions such as temperature fluctuations, moisture, and pressure.

- Advancements in nanotechnology to enhance adhesive properties, especially in microelectronics.

- Exploration of alternative bonding technologies, such as laser welding, to reduce dependency on adhesives.

Future Outlook for the Electronics Adhesives Market

- Forecasted continued growth in the market as new applications for adhesives emerge in electronics.

- Innovations in biodegradable and environmentally friendly adhesives expected to gain traction.

- Potential for increased integration of adhesive technologies in emerging markets such as 5G and AI-powered electronics.

- Ongoing development of advanced adhesives designed for specific applications, including semiconductors and printed circuit boards (PCBs).

- A shift towards automated adhesive dispensing systems to increase precision and reduce labor costs in electronics manufacturing.