Introduction

The flooring market relies on a complex global supply chain to source raw materials, manufacture products, and distribute them efficiently. However, various logistics challenges, ranging from raw material shortages to transportation delays, impact the industry's ability to meet demand. This article explores the key supply chain and logistics challenges in the flooring market and strategies to mitigate them.

Key Supply Chain Challenges

1. Raw Material Shortages

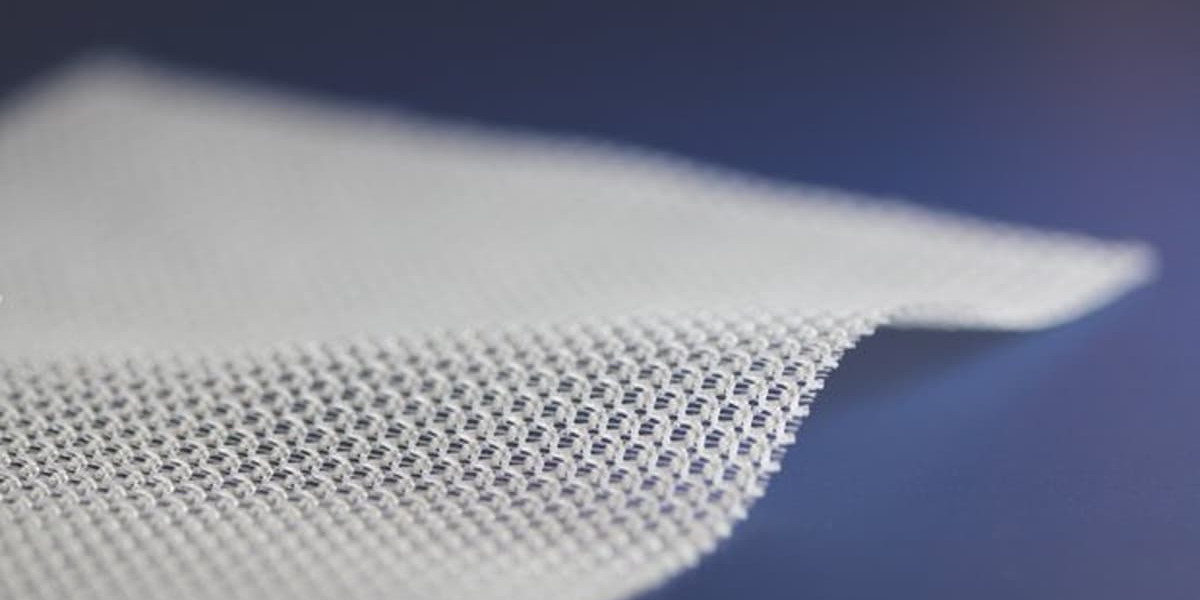

The flooring industry depends on materials such as wood, vinyl, ceramic, and carpets, which can be affected by supply constraints. Factors like deforestation restrictions, trade tariffs, and increased demand for sustainable materials contribute to raw material shortages, leading to production slowdowns and cost fluctuations.

2. Price Volatility in Raw Materials

Fluctuating costs of essential materials like timber, petroleum-based vinyl, and adhesives create uncertainty in pricing strategies. Rising energy costs and global economic conditions further exacerbate these challenges, making cost management difficult for manufacturers and distributors.

3. Manufacturing Delays and Capacity Constraints

Production bottlenecks caused by factory shutdowns, labor shortages, and increased global demand have led to longer lead times. Limited manufacturing capacity, especially in regions heavily impacted by labor disruptions, further strains the supply chain.

4. Global Trade and Tariff Barriers

The flooring market is heavily influenced by international trade policies. Tariffs and import/export restrictions can increase costs and delay shipments. Political instability and changes in trade agreements also create uncertainty in supply chain planning.

5. Sustainability and Regulatory Compliance

As environmental regulations tighten, manufacturers face increased scrutiny over sourcing practices, waste management, and carbon footprint reduction. Compliance with eco-certifications and sustainable forestry practices can create additional supply chain complexities.

Logistics Challenges in the Flooring Market

1. Transportation and Shipping Delays

Global shipping disruptions, container shortages, and port congestion significantly impact the flooring industry’s logistics. Long transit times and rising freight costs make it challenging for businesses to maintain consistent inventory levels.

2. Warehousing and Inventory Management

Efficient storage and distribution of flooring products require substantial warehouse space, especially for bulky materials like hardwood and ceramic tiles. Poor inventory forecasting can lead to stockouts or overstocking, affecting profitability.

3. Last-Mile Delivery Issues

Delivering flooring products to retailers, construction sites, or end consumers can be complicated due to weight, size, and handling requirements. Logistics providers must ensure careful handling to avoid damage, which adds complexity to last-mile operations.

4. Rising Fuel and Transportation Costs

The increasing cost of fuel directly impacts transportation expenses, making it more expensive to move flooring products across long distances. This challenge forces companies to optimize distribution networks and explore alternative transport methods.

Strategies to Overcome Supply Chain and Logistics Challenges

1. Diversification of Suppliers

To mitigate raw material shortages and price volatility, companies can establish multiple sourcing channels, including domestic and international suppliers. This reduces dependency on a single source and enhances supply chain resilience.

2. Investment in Digital Supply Chain Management

Adopting technology-driven solutions, such as AI-based demand forecasting, blockchain for tracking shipments, and automated inventory management, helps improve efficiency and reduce disruptions.

3. Sustainable and Localized Sourcing

Investing in sustainable materials and sourcing from regional suppliers can minimize environmental impact while reducing shipping times and costs. Certifications like FSC (Forest Stewardship Council) and LEED (Leadership in Energy and Environmental Design) help ensure compliance with green building standards.

4. Improving Warehousing and Distribution Networks

Optimizing warehouse locations, using automated storage solutions, and implementing just-in-time inventory management can enhance supply chain efficiency and reduce costs.

5. Strengthening Logistics Partnerships

Building strong relationships with third-party logistics providers (3PLs) ensures better transportation planning, reduces last-mile delivery challenges, and improves overall supply chain efficiency.

Future Outlook

The flooring industry must adapt to ongoing supply chain disruptions by embracing digital transformation, sustainability initiatives, and strategic logistics planning. Companies that invest in resilient supply chain solutions will have a competitive edge in overcoming market challenges and ensuring long-term growth.

Conclusion

The flooring market faces significant supply chain and logistics challenges, from raw material shortages to transportation bottlenecks. However, businesses can navigate these challenges by diversifying suppliers, leveraging digital technologies, and adopting sustainable sourcing practices. As the industry evolves, companies that proactively address supply chain risks will be better positioned for success in an increasingly competitive market.