The electric vehicle battery adhesive market is experiencing a surge in adoption as automakers increasingly recognize the advantages of advanced bonding solutions over traditional fastening methods. As EV production scales up to meet consumer demand, regulatory requirements, and technological advancements, adhesives are becoming a critical component in battery design and assembly.

This article explores the key factors driving the adoption of advanced adhesives in EV batteries and why automakers are making the shift.

1. Increasing Demand for Lightweight EVs

Weight reduction is a top priority in EV manufacturing, as lighter vehicles improve energy efficiency and driving range. Adhesives are replacing mechanical fasteners to achieve this goal.

How Adhesives Contribute to Lightweighting:

Structural adhesives reduce the need for heavy screws and bolts.

Thin-film adhesives enable compact and lightweight battery module designs.

Hybrid bonding solutions offer high strength with minimal material weight.

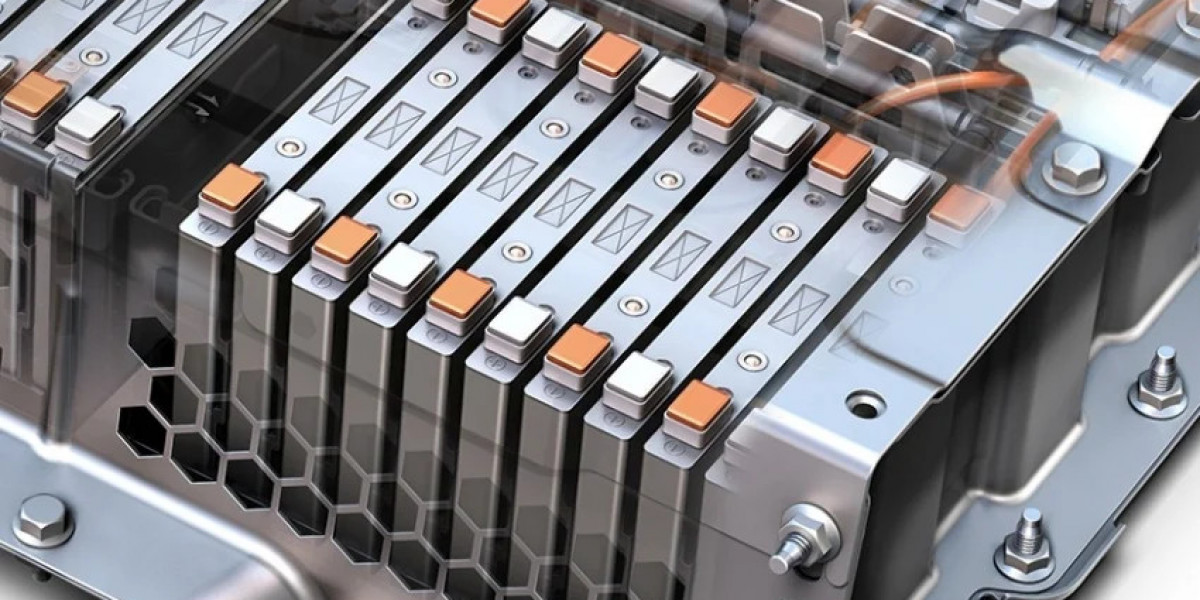

2. Enhancing Battery Safety and Structural Integrity

Safety remains a critical concern for automakers, particularly in battery enclosure design and crash resistance.

Safety Improvements Through Adhesives:

Impact-resistant adhesives absorb shock and vibrations, protecting battery cells.

Flame-retardant adhesives help prevent thermal runaway.

Electrically insulating adhesives prevent short circuits and leakage currents.

3. Growing Need for Thermal Management Solutions

As fast-charging technology and high-capacity batteries become the industry norm, managing heat buildup is essential for battery longevity and performance.

Adhesive Innovations for Thermal Management:

Thermally conductive adhesives dissipate excess heat, preventing battery degradation.

Silicone-based adhesives withstand extreme temperatures without losing effectiveness.

Phase-change adhesives regulate temperature fluctuations, enhancing battery stability.

4. Rise of Solid-State and High-Energy-Density Batteries

The transition from lithium-ion to solid-state batteries is pushing automakers to explore new adhesive solutions.

Adhesive Benefits for Next-Generation Batteries:

Flexible adhesives accommodate expansion and contraction of battery cells.

Low-outgassing adhesives prevent contamination in solid-state battery production.

High-strength bonding solutions ensure structural integrity in compact designs.

5. Sustainability and Regulatory Compliance

Governments worldwide are tightening environmental regulations, leading automakers to adopt eco-friendly adhesives that support sustainability goals.

Eco-Friendly Adhesive Innovations:

Low-VOC and solvent-free adhesives reduce harmful emissions.

Recyclable adhesives enable easier battery pack disassembly.

Bio-based adhesives provide a greener alternative to traditional bonding agents.

6. Faster Production and Automation in EV Manufacturing

With EV production scaling up, automakers require fast-curing adhesives that integrate with automated manufacturing processes.

Efficiency-Boosting Adhesive Solutions:

UV-curable adhesives that set within seconds, speeding up production.

Two-component adhesives for rapid assembly and curing.

Robotic adhesive application for precision and reduced material waste.

7. Cost Reduction and Long-Term Durability

Adhesives offer a cost-effective solution for battery assembly by reducing material usage and improving long-term battery reliability.

Cost and Durability Benefits:

Lower manufacturing costs due to reduced material and assembly complexity.

Extended battery life through better thermal and structural stability.

Fewer warranty claims due to enhanced battery pack durability.

Conclusion: The Future of Adhesives in EV Battery Manufacturing

As automakers continue to refine EV designs, the electric vehicle battery adhesive market will play a pivotal role in shaping safer, lighter, and more efficient batteries. With sustainability, automation, and performance driving adoption, adhesives are set to become the industry standard in next-generation EV battery assembly.

Read more at https://www.pristinemarketinsights.com/electric-vehicle-battery-adhesive-market-report