Introduction

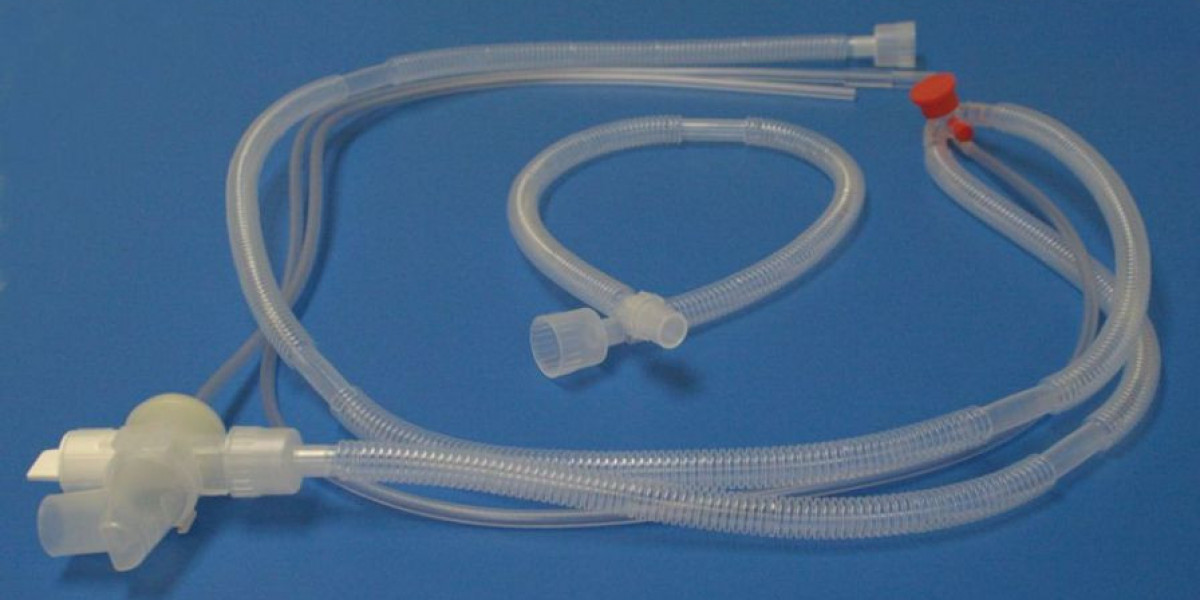

The breathing circuit market is subject to stringent regulatory frameworks and compliance requirements to ensure patient safety, product quality, and efficacy. Manufacturers must navigate complex approval processes set by global regulatory bodies such as the U.S. Food and Drug Administration (FDA), the European Medicines Agency (EMA), and other international health authorities. This article explores the regulatory landscape, key compliance requirements, and challenges that shape the global breathing circuit market.

Regulatory Framework Governing the Breathing Circuit Market

To ensure safety and effectiveness, breathing circuits must comply with various national and international standards. Key regulatory bodies overseeing the market include:

U.S. Food and Drug Administration (FDA)

The FDA classifies breathing circuits as Class II medical devices, requiring premarket notification (510(k)) or, in some cases, premarket approval (PMA) to demonstrate safety and effectiveness.

Compliance with Good Manufacturing Practices (GMP) under the Quality System Regulation (QSR) is mandatory.

European Medicines Agency (EMA) and CE Marking

In the European Union, breathing circuits must comply with the Medical Devices Regulation (MDR 2017/745) and obtain CE marking, signifying compliance with health, safety, and environmental protection standards.

The conformity assessment process involves Notified Bodies that verify compliance before market entry.

International Organization for Standardization (ISO) Standards

ISO 5367:2014 specifies requirements for breathing circuit components used in medical settings, ensuring reliability and patient safety.

ISO 13485 outlines the quality management system standards for medical device manufacturing.

Other Global Regulatory Authorities

In Japan, the Pharmaceuticals and Medical Devices Agency (PMDA) oversees medical device approvals.

China's National Medical Products Administration (NMPA) regulates the import and manufacturing of breathing circuits.

Health Canada requires manufacturers to obtain a Medical Device License (MDL) before market entry.

Compliance Requirements and Quality Standards

Manufacturers and distributors must adhere to several compliance and quality assurance measures, including:

Material and Biocompatibility Testing

Ensuring breathing circuits are made from non-toxic, biocompatible materials that meet ISO 10993 testing standards.

Sterilization and Hygiene Standards

Compliance with sterilization protocols such as ISO 11135 (ethylene oxide sterilization) or ISO 17665 (steam sterilization) to prevent contamination.

Performance and Safety Evaluations

Testing for pressure resistance, leakage prevention, and durability under clinical conditions.

Labeling and Documentation Compliance

Proper labeling with usage instructions, safety warnings, and compliance markings (e.g., FDA approval, CE mark).

Post-Market Surveillance and Adverse Event Reporting

Regulatory bodies require continuous monitoring of product performance, including adverse event reporting and periodic audits.

Challenges in Regulatory Compliance

While regulations ensure product safety and effectiveness, they also pose challenges for manufacturers:

Evolving Regulatory Requirements

Compliance regulations are constantly updated, requiring manufacturers to stay informed and adapt their processes.

High Costs of Certification and Compliance

Obtaining regulatory approvals, conducting clinical trials, and ensuring quality control require significant financial investment.

Market Entry Barriers in Different Regions

Varying regulatory standards across countries make it challenging for companies to launch products simultaneously in multiple markets.

Counterfeit and Substandard Products

The presence of low-quality, non-compliant breathing circuits in the market poses risks to patient safety and regulatory enforcement.

Strategic Recommendations for Compliance Success

Invest in Regulatory Expertise

Companies should establish dedicated regulatory affairs teams to ensure compliance with evolving global standards.

Leverage Digital Documentation and Quality Management Systems

Implementing electronic quality management systems (eQMS) can streamline compliance processes and improve audit readiness.

Engage in Early Regulatory Consultations

Partnering with regulatory consultants or engaging in pre-submission meetings with authorities can expedite the approval process.

Focus on Sustainable and Regulatory-Compliant Manufacturing

Developing eco-friendly, biocompatible, and sterilizable breathing circuits can align with both regulatory requirements and market demand.

Conclusion

The regulatory landscape for the breathing circuit market is complex but essential for ensuring product safety, efficacy, and global market access. Compliance with FDA, EMA, ISO, and other regulatory standards is critical for manufacturers to establish credibility and expand their market presence. By adopting proactive regulatory strategies, investing in quality management systems, and staying ahead of evolving compliance trends, industry players can navigate regulatory challenges and drive long-term success in the global healthcare market.