The automotive heat shield market plays an essential role in enhancing vehicle performance, safety, and efficiency by protecting critical components from excessive heat. With growing demand for fuel-efficient vehicles and the rapid adoption of electric vehicles (EVs), the market has witnessed significant innovation and expansion. However, despite these advances, several inhibitors continue to restrain its full potential. From rising raw material costs to complex design requirements and stringent environmental regulations, various challenges are slowing the market's growth trajectory. This article delves into the major inhibitors currently affecting the automotive heat shield market and how they impact both manufacturers and end-users.

1. High Raw Material Costs

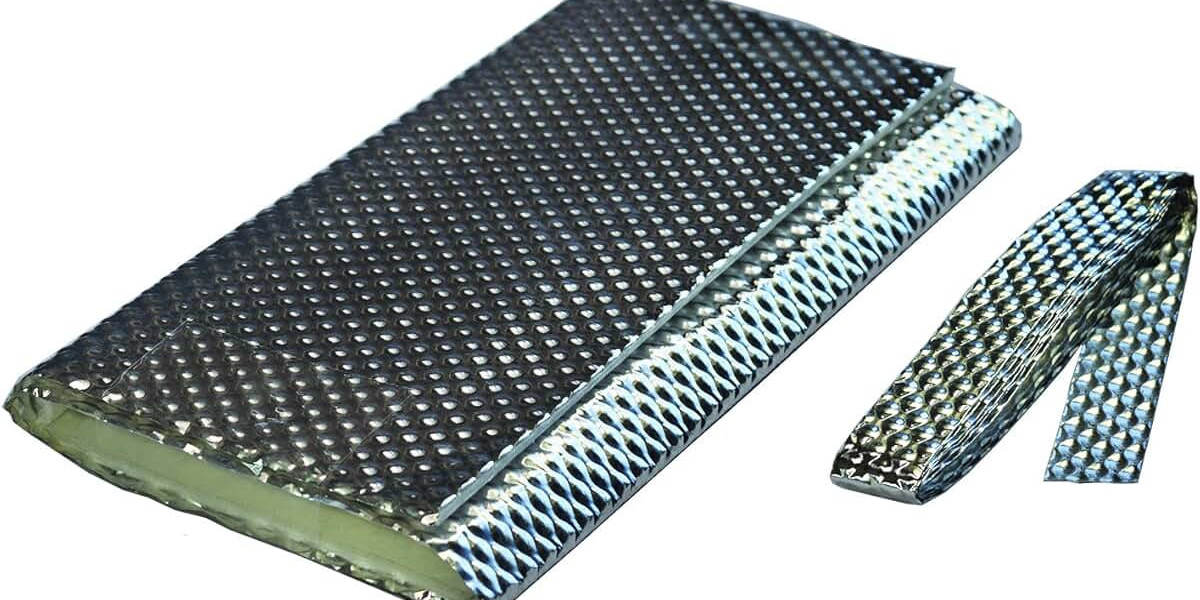

One of the most pressing challenges facing the automotive heat shield market is the rising cost of raw materials. Advanced heat shields are often made from specialized materials such as aluminum, stainless steel, ceramic composites, and multi-layered fabrics. These materials offer excellent thermal resistance and durability but come at a premium price.

As global demand for high-performance materials increases, supply chain pressures and fluctuating commodity prices contribute to rising manufacturing costs. This directly affects profit margins for manufacturers, particularly small and medium-sized enterprises that struggle to compete with larger players in cost-sensitive markets. Moreover, as electric vehicles require more advanced thermal management, the demand for costlier materials further compounds this challenge.

2. Design and Engineering Complexities

Another major inhibitor is the increasing complexity of designing and engineering heat shields for modern vehicles. Automobiles today are more compact, integrated, and technologically advanced than ever before. This makes it difficult to design heat shields that not only meet performance expectations but also fit within limited engine and cabin space.

Heat shields must now be tailored for different vehicle models, powertrain configurations, and heat generation zones. For electric vehicles, the design must address battery protection, electronic components, and cooling systems. Meeting these diverse requirements demands intensive R&D, advanced simulation tools, and prototype testing — all of which increase development time and cost.

The integration of lightweight solutions also adds pressure, as manufacturers must strike a balance between thermal protection and weight reduction to maintain fuel efficiency. These engineering complexities make it difficult for new players to enter the market and for existing companies to scale rapidly.

3. Regulatory and Compliance Barriers

Environmental and safety regulations are becoming more stringent globally, especially concerning emissions, noise levels, and thermal safety. While these regulations are essential for public health and environmental sustainability, they can pose significant challenges for heat shield manufacturers.

Compliance requires continuous monitoring of changing standards, investment in certification processes, and the adaptation of manufacturing practices to meet new criteria. In some regions, the lack of harmonized global standards makes it even more challenging for manufacturers to produce a single product suitable for all markets.

Failure to comply with evolving regulations can result in costly recalls, fines, and reputational damage. For smaller businesses, the burden of regulatory compliance can be particularly overwhelming and can limit their ability to compete in international markets.

4. Supply Chain Disruptions

The global automotive supply chain has faced unprecedented disruptions in recent years due to factors such as the COVID-19 pandemic, geopolitical conflicts, and shipping delays. These disruptions have affected the availability of raw materials and delayed the delivery of essential components, including those required for heat shield manufacturing.

The reliance on specific suppliers for high-quality materials, such as advanced aluminum alloys or high-temperature coatings, has exposed manufacturers to risks of shortages and price volatility. Lead times for raw materials and production components have increased, causing delays in product development and order fulfillment.

These supply chain issues make it difficult for manufacturers to meet the demands of OEMs (Original Equipment Manufacturers) and tier-one suppliers, potentially resulting in lost contracts and revenue.

5. Limited Awareness and Aftermarket Penetration

While OEM demand for heat shields is strong, the aftermarket segment still faces limited awareness and adoption. Many vehicle owners are not fully aware of the importance of maintaining or upgrading heat shields, especially in regions where vehicle servicing focuses primarily on more visible components like brakes, tires, or exhaust systems.

This lack of consumer awareness inhibits aftermarket growth, limiting opportunities for manufacturers to generate additional revenue beyond OEM contracts. Educating consumers about the long-term benefits of heat shields, including better performance and reduced wear on components, remains a challenge for the industry.

6. Technological Obsolescence and Rapid Changes

Rapid technological evolution in automotive design — particularly with electric and hybrid vehicles — can render existing heat shield technologies obsolete in a short span. Manufacturers must constantly innovate and adapt to new vehicle architectures, materials, and performance standards.

However, this need for continual evolution puts pressure on companies to invest heavily in R&D, retooling, and workforce training. For some firms, especially smaller or resource-constrained ones, keeping pace with this rapid change becomes an inhibitor to sustained growth and market relevance.

Conclusion

While the automotive heat shield market holds substantial promise, several inhibitors continue to challenge its growth and innovation. High material costs, design complexities, regulatory pressures, supply chain disruptions, limited consumer awareness, and fast-paced technological changes all contribute to slowing momentum.

Overcoming these inhibitors will require a combination of strategies — including investing in material research, enhancing global supply chain resilience, simplifying regulatory compliance, and raising awareness among end-users. As the automotive industry continues to evolve, companies that successfully navigate these barriers will be best positioned to capitalize on future opportunities and maintain a competitive edge in the global market.

Learn more: https://www.pristinemarketinsights.com/automotive-heat-shield-market-report