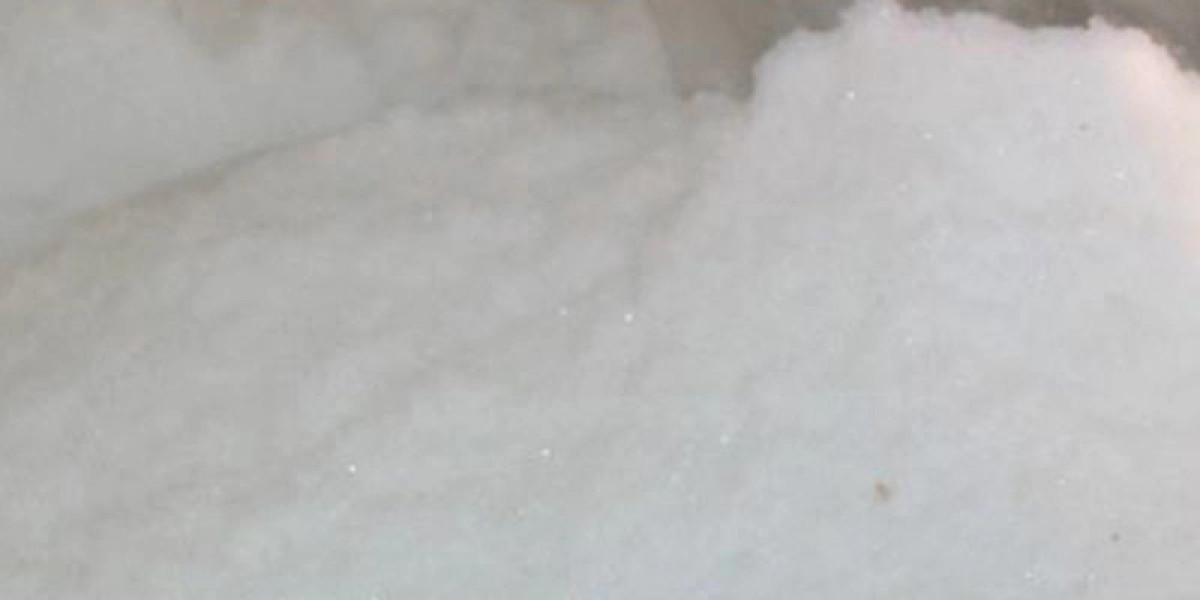

The monochloroacetic acid market is experiencing considerable growth, driven by its versatile applications across sectors like agriculture, textiles, and personal care. However, despite the positive market outlook, there are several challenges that continue to pose difficulties for manufacturers and distributors. These challenges are especially prominent in the handling, storage, and distribution chains, where the chemical's reactive nature, potential hazards, and regulatory compliance requirements complicate its logistics and supply chain management.

One of the primary challenges in the monochloroacetic acid market lies in the safe handling and storage of the chemical. Monochloroacetic acid is a highly reactive substance, and its corrosive properties can present significant safety risks during transportation and storage. This necessitates the use of specialized containers and storage facilities that can withstand its corrosive nature and prevent leaks or accidental exposure. Ensuring the safety of workers and preventing environmental contamination are major concerns, as improper handling can lead to hazardous situations. As such, manufacturers and distributors must invest in rigorous safety protocols, training programs, and infrastructure to manage the risks associated with monochloroacetic acid.

Furthermore, the chemical’s highly reactive nature demands a careful approach when it comes to transportation. Monochloroacetic acid must be transported in containers that can safely contain it without the risk of contamination or deterioration during transit. This requires adherence to strict regulations governing the safe transportation of hazardous chemicals, which can increase logistics costs. In many regions, regulations surrounding the movement of hazardous materials are continually evolving, which adds complexity to the distribution process. Keeping up with these ever-changing requirements presents an ongoing challenge for manufacturers and distributors, who must ensure compliance while maintaining efficient and cost-effective supply chains.

The distribution chain itself is also affected by the limited shelf life and the potential for degradation of monochloroacetic acid during storage. Once produced, the chemical needs to be distributed quickly and efficiently to maintain its quality and effectiveness. Delays in transportation or inadequate storage conditions can lead to degradation, which compromises the chemical’s quality and could result in financial losses for manufacturers and distributors. Additionally, the need for temperature-controlled storage or the use of special packaging materials further complicates logistics, making it critical for companies to establish robust supply chain strategies that ensure the safe and timely delivery of monochloroacetic acid.

Another challenge lies in the growing global demand for monochloroacetic acid, particularly in emerging markets. While the demand is rising in regions like Asia-Pacific and Latin America, the infrastructure and regulatory frameworks in these markets may not always align with the sophisticated handling and storage requirements of monochloroacetic acid. This creates a situation where companies must invest in local supply chain infrastructure or partner with local logistics providers to ensure safe and compliant distribution, all of which can drive up costs.

Additionally, the market’s focus on sustainability and environmental responsibility adds another layer of complexity to the handling, storage, and distribution of monochloroacetic acid. As regulatory standards surrounding environmental protection become more stringent, companies must find ways to manage waste and emissions generated during the production and distribution of monochloroacetic acid. Innovations in packaging and transport methods that reduce environmental impact, such as using biodegradable or recyclable materials, are in demand, but they often come with additional costs and logistical challenges.

In conclusion, despite the promising growth of the monochloroacetic acid market, challenges related to handling, storage, and distribution continue to persist. Manufacturers and distributors must navigate these hurdles by investing in safety measures, adhering to evolving regulations, and adopting efficient supply chain strategies. While the demand for monochloroacetic acid is expected to rise, overcoming these logistical challenges is crucial for ensuring the chemical’s continued success in the market. Companies that can effectively manage these issues while maintaining safety, quality, and sustainability will be better positioned to thrive in an increasingly competitive and regulated industry.

Read more https://www.pristinemarketinsights.com/monochloroacetic-acid-market-report