The 3D Printing Market is progressing rapidly, with a notable shift towards the integration of artificial intelligence (AI) and automation technologies. These advancements are revolutionizing the way products are designed, printed, and assembled, significantly improving the efficiency, speed, and accuracy of 3D printing processes. In this blog, we explore how AI and automation are reshaping the landscape of the 3D Printing Market, driving innovation, and enabling industries to achieve greater production capabilities and cost-effectiveness.

AI and Automation: A Game-Changer for 3D Printing

The integration of AI and automation technologies is proving to be a game-changer for the 3D Printing Market, enabling manufacturers to optimize production processes and enhance the capabilities of 3D printing technology. Here are some of the key ways in which these technologies are transforming the industry:

AI-Driven Design Optimization: One of the most significant contributions of AI to 3D printing is in the design optimization process. AI algorithms can analyze complex design structures and identify areas for improvement, such as reducing material usage, enhancing structural integrity, or optimizing for faster printing. This is particularly important in industries like aerospace, automotive, and healthcare, where precision and material efficiency are crucial. AI-driven design tools can help designers create optimized models that are not only lighter but also stronger and more cost-effective to produce.

Predictive Maintenance and Process Monitoring: Automation and AI are enhancing the reliability of 3D printing machines by enabling predictive maintenance and continuous process monitoring. AI-powered sensors and analytics can track the condition of 3D printers in real time, identifying potential issues before they become major problems. This helps reduce downtime, increase printer longevity, and improve overall production efficiency. Predictive maintenance also ensures that machines are always running at optimal performance, minimizing the risk of defects and waste during the printing process.

Quality Control and Defect Detection: AI is also playing a crucial role in improving the quality control of 3D-printed parts. Machine learning algorithms can analyze the quality of printed components by comparing them to a digital model or using visual inspection techniques. If any defects or discrepancies are detected, the system can alert operators to make adjustments before the production process continues. This not only enhances product quality but also reduces the need for post-production repairs and rework, saving time and resources.

Automation in Post-Processing: Post-processing is a crucial step in 3D printing, often involving processes like cleaning, curing, and finishing of printed parts. Automation technologies are streamlining these processes, reducing the need for manual intervention and improving throughput. Automated post-processing systems can handle tasks such as material removal, surface polishing, and inspection, allowing for faster turnaround times and more consistent results.

Robotic Systems for Assembly and Handling: Robotics is another key component of automation in 3D printing. Robotic arms can be used to handle printed parts during the production process, removing them from the printer, assembling them into larger structures, or preparing them for post-processing. Robotic systems are also used to handle multiple 3D printers simultaneously, increasing the number of parts that can be produced in parallel and improving overall production capacity.

Enhanced Efficiency and Reduced Costs

The integration of AI and automation into the 3D Printing Market is leading to enhanced efficiency and cost reduction, making 3D printing a more attractive solution for a wide range of industries. Here’s how these technologies are driving down costs and improving production efficiency:

Faster Production Times: Automation speeds up various stages of the 3D printing process, from the printing itself to post-processing and assembly. AI-based tools can optimize print paths and speeds, reducing the time required to produce a part. Additionally, automated systems can operate 24/7, further accelerating production cycles and reducing lead times for customers. This is particularly valuable in industries like aerospace and automotive, where quick turnarounds are crucial for maintaining competitive advantage.

Material Efficiency: AI can also contribute to material efficiency by analyzing and optimizing the use of materials during the printing process. This ensures that only the necessary amount of material is used, reducing waste and lowering material costs. Moreover, AI systems can suggest alternative materials or processes that might be more cost-effective or environmentally friendly, further driving cost reductions.

Scalability: The integration of AI and automation makes it easier for companies to scale their 3D printing operations. Once a design has been optimized, automated systems can quickly replicate the production process across multiple machines, allowing manufacturers to meet higher demand without sacrificing quality or increasing costs. This scalability is a key factor in making 3D printing a viable solution for mass production.

Reduced Labor Costs: Automation reduces the need for manual labor in many aspects of the 3D printing process. For example, robotic systems can handle repetitive tasks such as part removal, material application, and assembly, allowing human operators to focus on higher-level decision-making and design tasks. This reduction in manual labor costs can significantly lower the overall cost of production.

Industries Benefiting from AI and Automation in 3D Printing

AI and automation are particularly beneficial in industries that require high precision, rapid production times, and cost-effective manufacturing solutions. Some of the key sectors benefitting from these technologies include:

Aerospace and Defense: In aerospace, AI and automation are used to optimize the production of lightweight, high-performance parts for aircraft and spacecraft. The ability to rapidly iterate designs and automate the printing and post-processing of parts has led to faster development cycles and reduced production costs for companies in the aerospace sector.

Automotive: The automotive industry is leveraging AI and automation to enhance vehicle design and manufacturing. From prototyping new parts to producing end-use components, AI-driven design optimization and automated production processes are improving efficiency and quality in automotive manufacturing. Companies can also use these technologies to produce customized parts for customers or to produce complex, lightweight components that improve vehicle performance.

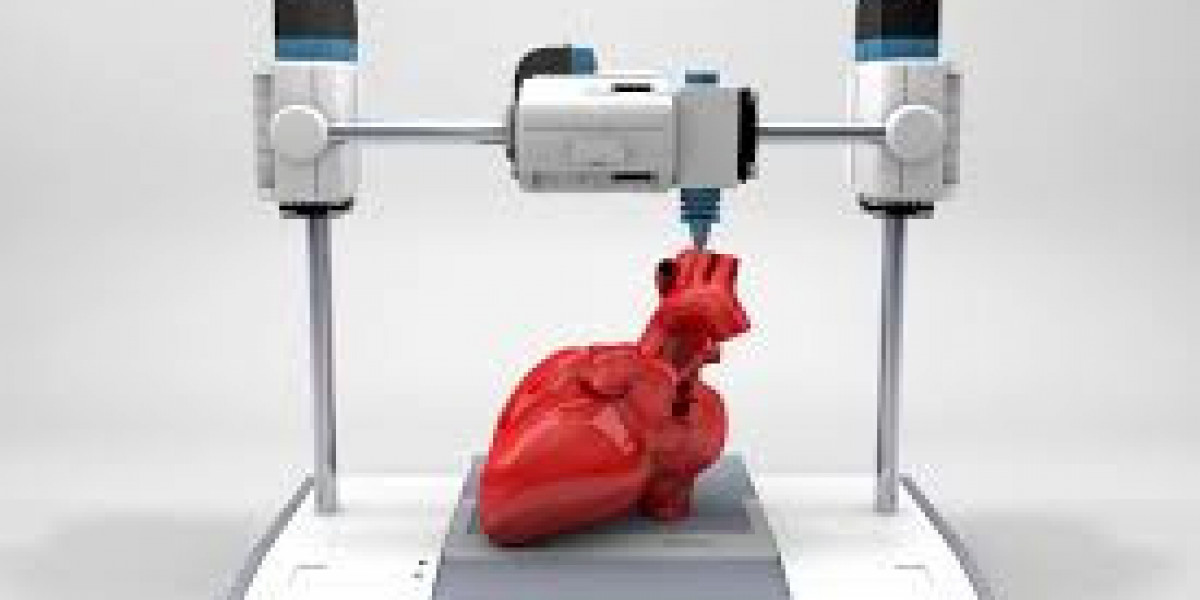

Healthcare: The healthcare sector is benefiting from AI and automation in 3D printing, particularly in the production of customized medical devices, prosthetics, and implants. AI-driven design tools allow for the creation of personalized solutions that are tailored to individual patients' needs, while automation speeds up production times and reduces errors. These technologies are also used to manufacture surgical tools and implants with high precision, improving patient outcomes.

Consumer Goods: In the consumer goods sector, AI and automation in 3D printing are helping manufacturers produce personalized products at scale. From custom jewelry to bespoke footwear, these technologies enable companies to offer highly individualized products while maintaining production efficiency. AI can also help optimize the design of consumer goods, ensuring that products are both aesthetically pleasing and functional.

Industrial Manufacturing: Industrial manufacturers are increasingly adopting AI and automation technologies to streamline the production of tools, machinery parts, and production aids. These technologies improve the precision and efficiency of manufacturing processes, allowing companies to meet tight deadlines and reduce operational costs.

The Future of AI and Automation in the 3D Printing Market

The integration of AI and automation into the 3D Printing Market is expected to continue growing in the coming years. As AI technologies advance and automation systems become more sophisticated, manufacturers will be able to produce even more complex and customized parts at scale. Additionally, as the cost of these technologies decreases, they will become more accessible to small and medium-sized enterprises, further accelerating the adoption of 3D printing across various industries.

The future of 3D printing will likely see more widespread use of autonomous production systems, where AI and automation handle everything from design to production and quality control. This will make 3D printing more efficient, cost-effective, and scalable, opening up new opportunities for innovation and market growth.

Conclusion

The 3D Printing Market is experiencing significant growth, thanks to the integration of AI and automation technologies. These advancements are improving efficiency, reducing costs, and driving innovation across various industries. As these technologies continue to evolve, the potential for 3D printing will expand, enabling manufacturers to create more complex, customized, and high-quality products at a faster rate. With the growing role of AI and automation, the future of 3D printing looks incredibly promising, offering boundless opportunities for industries to optimize their production processes and improve their bottom line.