The machine safety market is poised for significant growth over the coming years, driven by increasing emphasis on worker safety, industrial automation, and stringent regulatory compliance across various industries. Machine safety refers to the integration of protective mechanisms and control systems that ensure machinery operates safely and prevents accidents during operation. These systems are crucial in sectors such as manufacturing, automotive, aerospace, food and beverages, and pharmaceuticals, where the use of automated equipment is extensive.

Market Overview

As industries adopt Industry 4.0 and digital transformation initiatives, safety is becoming an integral part of the design and operation of machines. The machine safety market is projected to grow steadily, supported by rising awareness of workplace hazards and the need for compliance with international safety standards such as ISO 13849 and IEC 62061. The global market, which was valued at approximately USD 4.5 billion in 2023, is expected to reach around USD 6.8 billion by 2030, growing at a compound annual growth rate (CAGR) of nearly 6.0%.

Drivers of Market Growth

Several key factors are contributing to the expansion of the machine safety market:

Increased Industrial Automation: With industries increasingly turning to automation to enhance productivity and reduce human errors, the implementation of machine safety systems becomes essential. Automated environments require advanced safety solutions to protect both human operators and expensive machinery.

Regulatory Compliance: Governments and international bodies are enforcing strict safety regulations to reduce workplace accidents. Compliance with OSHA (Occupational Safety and Health Administration), ANSI (American National Standards Institute), and EU Machinery Directives has made it mandatory for organizations to incorporate safety systems into their operations.

Rise in Workplace Accidents: The rising number of workplace accidents has created urgency among manufacturers to improve safety systems. This is especially true in heavy-duty sectors like construction, mining, and manufacturing, where machinery-related accidents are more frequent and can lead to significant human and financial losses.

Technological Advancements: Innovation in machine safety technology, such as the use of IoT-enabled safety devices, AI-driven predictive maintenance, and wireless safety sensors, has improved the performance and reliability of these systems. These technologies are also easier to integrate into modern smart factories.

Key Components and Systems

Machine safety systems typically include a range of components, such as:

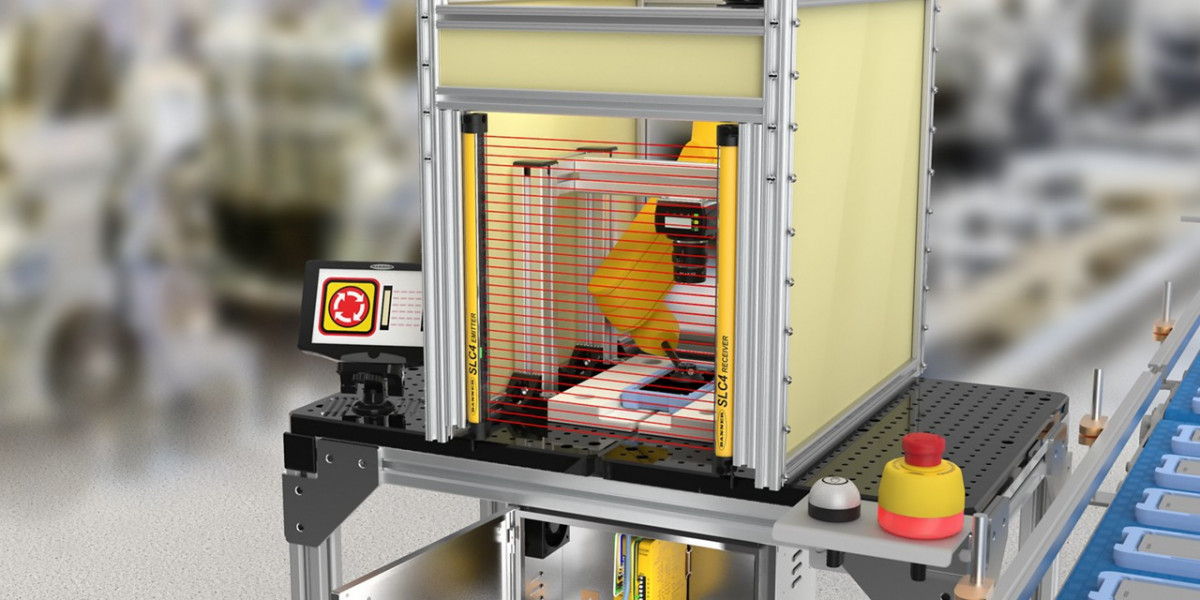

Safety Light Curtains: Used to protect operators from hazardous machine parts.

Emergency Stop Devices: Allow immediate shutdown of equipment in case of danger.

Safety Relays and Controllers: Manage signals from safety devices to initiate appropriate responses.

Interlock Switches: Prevent machine operation when doors or guards are open.

These components are commonly used in combination to create layered safety strategies tailored to specific machinery and industrial needs.

Regional Insights

North America and Europe currently dominate the machine safety market due to early adoption of safety standards, strong regulatory frameworks, and advanced industrial infrastructure. However, the Asia-Pacific region is expected to witness the fastest growth during the forecast period. Rapid industrialization in countries like China, India, and Japan, combined with increasing awareness of workplace safety, is driving demand in the region. Additionally, government initiatives promoting manufacturing excellence and worker welfare are playing a critical role.

Challenges and Opportunities

While the market is growing, there are challenges that must be addressed:

High Implementation Costs: Small and medium-sized enterprises (SMEs) may find the initial costs of machine safety systems prohibitive, especially when integrating with legacy equipment.

Lack of Skilled Personnel: Operating and maintaining advanced safety systems require technical expertise, which may be lacking in some regions or industries.

However, these challenges also present opportunities for training, innovation, and the development of cost-effective solutions. As digital technologies become more accessible, even smaller companies will be able to integrate machine safety into their operations.

Future Outlook

The machine safety market will continue to grow as industries focus on smart manufacturing, operational efficiency, and employee safety. Innovations in AI, machine learning, and data analytics will further enhance the predictive and preventive capabilities of safety systems. Companies that invest early in advanced safety technologies will not only ensure compliance but also gain a competitive edge through reduced downtime, fewer accidents, and higher employee trust.