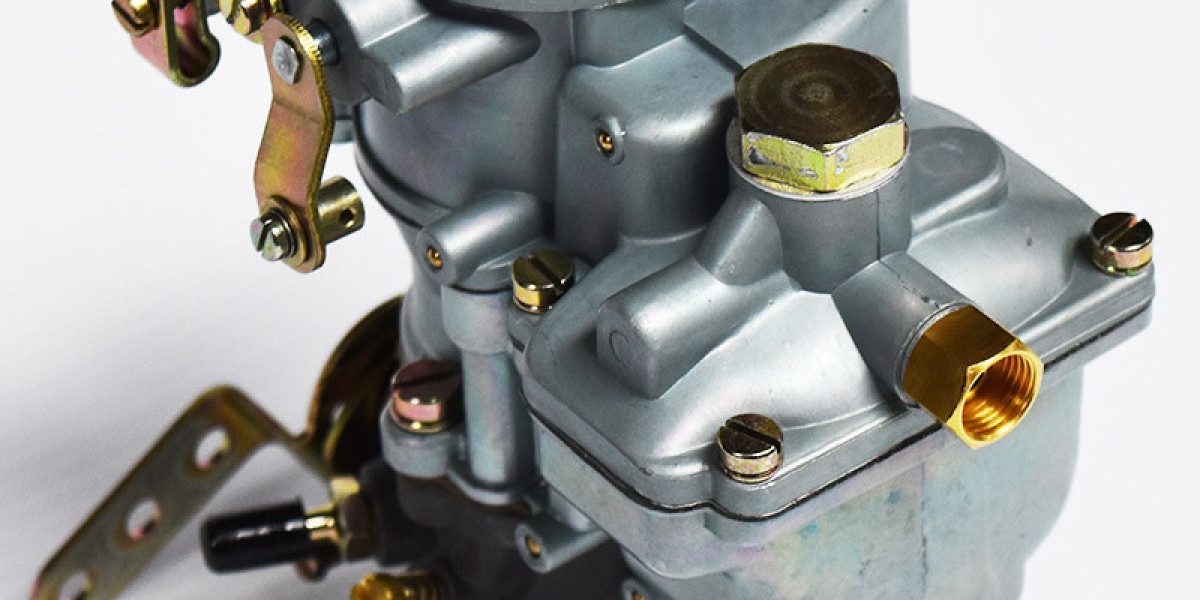

The carburettor market has played a crucial role in fuel delivery systems for internal combustion engines for decades. However, despite its historical significance, the market faces numerous hindrances that restrict growth and threaten its long-term sustainability. Rapid technological advancements, evolving regulatory landscapes, increasing competition from alternative fuel systems, and shifting consumer demands are some of the prominent challenges impacting the carburettor market globally. This article delves into these hindrances, analyzing their implications and how they shape the future outlook of the industry.

Technological Obsolescence and Shift to Electronic Fuel Injection

One of the most significant hindrances to the carburettor market is the global transition toward electronic fuel injection (EFI) systems. EFI offers precise and dynamic fuel delivery control, improving engine efficiency, lowering emissions, and enhancing overall vehicle performance.

Carburettors, by comparison, rely on mechanical processes that lack the adaptability and accuracy of EFI systems. This technological gap causes many manufacturers to phase out carburettors in favor of EFI, especially in passenger cars, commercial vehicles, and high-performance motorcycles.

The widespread adoption of EFI technology thus restricts the demand for carburettors, limiting market growth and pressuring manufacturers to either innovate or exit.

Stringent Emission and Environmental Regulations

Global emission standards are becoming increasingly strict, with regulations such as Euro 6/7, Bharat Stage VI, and others enforcing lower permissible limits on vehicle pollutants. Carburettors, due to their less precise fuel-air mixture control, struggle to meet these stringent emission norms consistently.

As a result, many markets have imposed restrictions on carburettor-equipped vehicles, accelerating their phase-out. This regulatory pressure presents a considerable barrier for carburettor manufacturers who face challenges in redesigning products to comply without incurring prohibitive costs.

Failure to meet emission standards restricts market access and dampens growth prospects, particularly in developed regions with rigorous environmental policies.

Competition from Alternative and Advanced Fuel Delivery Technologies

The carburettor market also suffers from intense competition posed by alternative fuel delivery systems. Besides EFI, direct injection, variable valve timing, and hybrid powertrains offer improved fuel efficiency and reduced emissions.

The growing trend toward hybrid and electric vehicles further diminishes the relevance of carburettors in new vehicle production. Although electric vehicle penetration remains limited in some regions, its growth trajectory threatens long-term demand.

This competition squeezes carburettor market share, forcing manufacturers to explore new applications or diversify product portfolios, which can be both costly and risky.

Changing Consumer Preferences and Awareness

Consumer preferences increasingly favor vehicles and machinery equipped with advanced, efficient, and environmentally friendly fuel systems. Awareness of fuel economy, emission standards, and performance reliability leads buyers to opt for EFI or newer technologies.

Carburettors are often perceived as outdated or less efficient, impacting their demand in urban and technologically advanced markets. This shift in preference creates a significant barrier for carburettor manufacturers trying to sustain sales in competitive environments.

Fuel Quality Sensitivity and Performance Issues

Carburettors require relatively clean and consistent fuel quality to operate effectively. Variability in fuel composition, such as ethanol blends and contaminants, can cause carburettor malfunction, leading to engine inefficiency and increased maintenance.

As fuel standards evolve globally and alternative fuels become more common, carburettors face growing technical challenges in adapting to these changes without compromising performance or reliability.

This sensitivity limits market expansion in regions with inconsistent fuel quality and adds to operational costs, creating a further hindrance.

High Maintenance Requirements Compared to Modern Systems

Unlike EFI systems, which are mostly self-regulating and require minimal maintenance, carburettors need regular cleaning, tuning, and servicing to maintain optimal performance.

This higher maintenance burden discourages end-users, especially in markets where convenience and low operating costs are priorities. Additionally, the need for skilled technicians familiar with carburettor technology restricts accessibility in some areas.

The maintenance intensity acts as a deterrent to wider adoption, particularly among newer vehicle buyers who expect hassle-free operation.

Economic Barriers and Production Cost Pressures

Economic challenges also hinder the carburettor market. Increasing raw material costs and labor expenses elevate production costs, narrowing profit margins.

At the same time, the price gap between carburettors and EFI systems is decreasing due to advances in electronic component manufacturing. This makes EFI a financially viable option even for cost-sensitive manufacturers, further limiting carburettor demand.

Reduced investment in carburettor research and development due to uncertain market prospects hampers innovation, making it difficult to compete with technologically advanced systems.

Geographical and Application Limitations

The carburettor market’s relevance is increasingly confined to specific geographies and applications. While demand persists in developing regions and certain sectors like motorcycles, small engines, and classic vehicles, mature markets are rapidly shifting toward modern alternatives.

This geographical segmentation limits economies of scale and complicates global marketing efforts for carburettor manufacturers. Moreover, the shrinking application scope confines growth potential and reduces the attractiveness of the market to investors.

Conclusion: Overcoming Hindrances for Market Sustainability

The carburettor market faces significant hindrances that constrain growth and challenge its sustainability. Technological obsolescence, regulatory restrictions, rising competition, and changing consumer attitudes form a complex barrier landscape.

Manufacturers must address these hindrances through innovation, adaptation to fuel and emission requirements, and diversification into niche markets. Without strategic responses, the carburettor market risks further decline in an industry increasingly dominated by advanced fuel technologies.

Understanding and mitigating these challenges is essential for stakeholders aiming to preserve carburettor relevance and profitability in an evolving automotive and machinery ecosystem.