The global transition to electric vehicles (EVs), renewable energy storage, and portable electronics has placed battery technology at the forefront of innovation. At the heart of this technology lies the battery electrode coating process, a critical component that significantly affects battery performance, longevity, and safety. Despite the growing demand, the battery electrode coating market faces several barriers that impede its growth and scalability. Understanding these obstacles is crucial for stakeholders seeking to navigate or invest in this evolving market.

1. High Capital Investment and Operational Costs

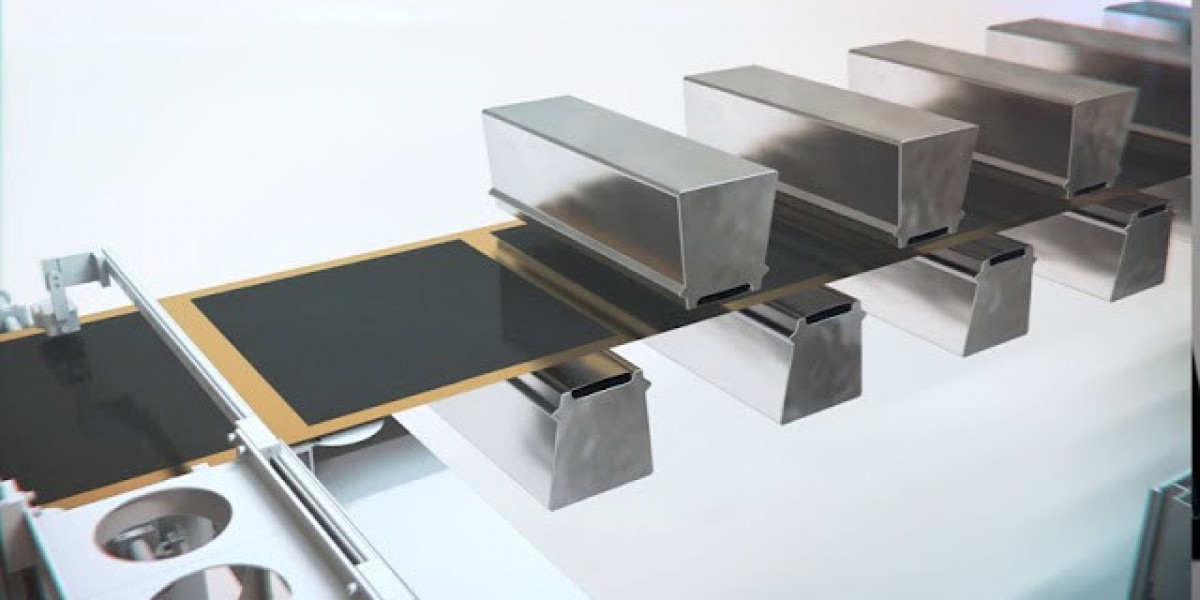

One of the most significant barriers in the battery electrode coating market is the high initial capital required for setting up advanced manufacturing facilities. Electrode coating processes demand specialized equipment such as slot-die coaters, vacuum drying ovens, and cleanroom environments to maintain product consistency. These setups require millions of dollars in investment, making it difficult for new entrants and small companies to participate.

Moreover, the operational costs associated with energy-intensive drying processes and solvent recovery systems can be substantial. These costs become even more pronounced when scaling up from pilot to commercial production, often requiring additional infrastructure and energy-efficient upgrades.

2. Technological Complexity and Process Optimization

Battery electrode coating is a highly precise process that must meet exact thickness, uniformity, and adhesion specifications. Achieving these standards consistently is technically challenging, especially as new chemistries and materials are introduced. For example, the use of solid-state electrolytes or silicon-based anodes requires different coating approaches, which can disrupt existing processes.

Variability in slurry composition, drying rates, and substrate quality can lead to defects such as delamination, cracking, or uneven coatings. These defects can significantly impact battery performance, leading to increased rejection rates and reduced profitability. As a result, extensive research and process optimization are required, adding to time and cost burdens.

3. Raw Material Supply Chain Constraints

Another pressing challenge is the volatility in the supply of key raw materials like lithium, cobalt, and nickel. Fluctuations in availability and price not only affect battery production costs but also influence the choice of electrode materials and coatings. Additionally, the sourcing of high-purity binders, solvents, and conductive additives is subject to geopolitical and environmental constraints.

The dependence on limited sources, especially from politically unstable regions, introduces risk into the supply chain. These issues can disrupt production timelines and lead to increased costs, further limiting the scalability of the coating market.

4. Environmental and Regulatory Pressures

As environmental regulations tighten globally, the battery manufacturing industry, including electrode coating, faces increasing pressure to reduce emissions and manage solvent waste. Traditional coating methods rely heavily on N-Methyl-2-pyrrolidone (NMP), a solvent known for its toxicity and environmental hazards. Although solvent-free and aqueous-based processes are emerging, they require re-engineering of equipment and processes, which can be costly and technically demanding.

Compliance with evolving environmental standards necessitates continuous monitoring, adaptation, and in many cases, retrofitting of existing facilities. This regulatory uncertainty can discourage investment and slow market growth.

5. Skilled Workforce and R&D Gaps

There is a shortage of highly trained professionals who specialize in battery chemistry, material science, and precision manufacturing. The lack of skilled talent hinders innovation and limits the ability of companies to implement advanced electrode coating techniques effectively. Moreover, the fast pace of technological advancement demands ongoing research and development (R&D), which not all companies can afford.

Insufficient collaboration between academia, research institutions, and industry further exacerbates this problem. Without strong partnerships and knowledge-sharing frameworks, it becomes difficult to accelerate innovation and overcome technical hurdles.

Conclusion

While the battery electrode coating market holds immense promise due to the surging demand for high-performance batteries, it is hindered by a range of technical, financial, regulatory, and logistical challenges. Addressing these barriers will require collaborative efforts across the industry, investment in R&D, and the development of cost-effective, sustainable coating technologies. Companies that can successfully navigate these hurdles will be well-positioned to lead in the next generation of battery innovation.