Shrink packaging is a popular method used in various industries for bundling and protecting products during storage, transportation, and display. Whether you’re packaging food items, electronics, or consumer goods, mastering the art of shrink packaging can help enhance efficiency, reduce waste, and elevate the presentation of your products. In this guide, we’ll explore tips and tricks for optimizing shrink packaging processes to achieve the best results.

1. Choose the Right Shrink Film:

Selecting the appropriate shrink film is crucial for achieving optimal results in shrink packaging. Consider factors such as film thickness, material composition, and shrinkage properties to ensure compatibility with your products and packaging equipment. Polyolefin and PVC are two common types of shrink films, each offering unique advantages in terms of clarity, strength, and shrinkability. Choose a film that provides sufficient protection and aesthetic appeal while meeting your specific packaging requirements.

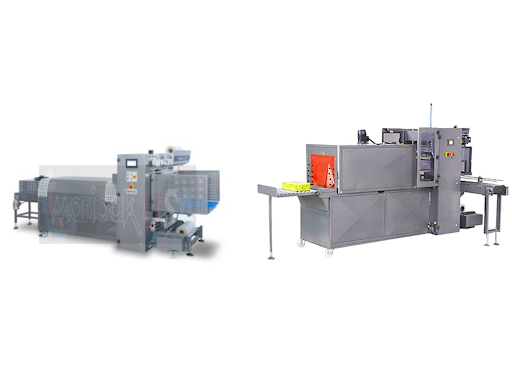

2. Optimize Packaging Equipment:

Investing in high-quality shrink packaging equipment can significantly improve efficiency and productivity. Whether you’re using a shrink bundler, shrink tunnel, or heat sealer, ensure that your equipment is properly maintained and calibrated for consistent performance. Adjust settings such as temperature, conveyor speed, and film tension to achieve the desired shrinkage and seal integrity. Regular maintenance and preventive upkeep are essential for prolonging the lifespan of your equipment and minimizing downtime.

3. Proper Product Handling and Preparation:

Before shrink-packaging your products, ensure they are properly handled and prepared for packaging. Remove any excess air or moisture from product packaging to prevent wrinkles or bubbles in the shrink film. Arrange products neatly and uniformly within the shrink film to ensure even shrinkage and optimal presentation. Consider using trays, pads, or dividers to separate and support products during the packaging process, especially for irregularly shaped or fragile items.

4. Consider Printed Shrink Film:

Printed shrink film offers an excellent opportunity to enhance product visibility and brand recognition. Consider customizing your shrink film with logos, graphics, or product information to create eye-catching packaging that attracts customers’ attention. Printed shrink film can also serve as a marketing tool, effectively communicating product features, benefits, and branding messages to consumers. Work with a reputable packaging supplier to design and produce custom-printed shrink film that aligns with your brand identity and packaging objectives.

5. Implement Quality Control Measures:

Maintaining consistent quality standards is essential for ensuring the integrity and reliability of shrink-packaged products. Implement quality control measures such as regular inspections, product testing, and process audits to identify and address any issues or defects promptly. Monitor key performance indicators such as seal strength, film clarity, and package aesthetics to gauge the effectiveness of your shrink packaging processes. By continuously monitoring and refining your operations, you can achieve consistent, high-quality results that meet customer expectations and enhance product satisfaction.

6. Environmental Considerations:

Incorporate eco-friendly practices into your shrink packaging processes to minimize environmental impact and meet sustainability goals. Choose biodegradable or recyclable shrink-bundler materials whenever possible to reduce waste and support environmentally responsible packaging solutions. Additionally, optimize packaging designs and material usage to minimize excess packaging and maximize resource efficiency. By prioritizing environmental considerations in shrink packaging, you can demonstrate your commitment to sustainability while meeting customer demand for eco-conscious products.

Conclusion: Elevate Your Packaging Game with Shrink Packaging

In conclusion, mastering shrink packaging requires careful attention to detail, proper equipment, and strategic planning. By following these tips and tricks, you can enhance efficiency, improve product presentation, and elevate the overall packaging experience for your products. Whether you’re bundling individual items or creating multipacks for retail display, shrink packaging offers a versatile and cost-effective solution for protecting and showcasing your products. Embrace shrink packaging as a valuable tool in your packaging arsenal and unlock opportunities to enhance brand visibility, attract customers, and drive sales in today’s competitive marketplace.